Interested in Learning More About our Vulcanator Rubber Granulator?

Advanced Rubber Granulation Solutions

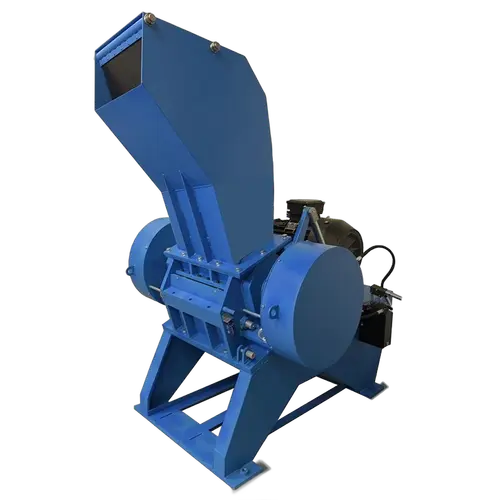

At Franklin Miller we offer advanced rubber processing solutions with their Vulcanator Rubber Granulator, designed to efficiently convert rubber bales into high-quality granules. The technology is energy-efficient, minimizes heat generation, and can be customized to meet the specific needs of various industries, including manufacturing, automotive, and construction.

Our Vulcanator Rubber Granulator is engineered to deliver the following benefits:

- Improved rubber processing efficiency

- High-quality end products

- Minimized heat generation during processing

- Energy-efficient operation

- Customizable to suit specific industry needs

1

Products

Since 1918

Established

Made in USA

Manufacturing

Livingston, NJ

Headquarters

How Our Vulcanator Rubber Granulator Works

Franklin Miller's Vulcanator Rubber Granulator is designed with cutting-edge technology to provide consistent performance and superior rubber granulation. The process involves the following steps:

- Feeding rubber into the Vulcanator Rubber Granulator

- Cutting and shredding the rubber into smaller granules with minimal heat generation

- Collecting the granulated rubber for further processing or recycling

Applications of Vulcanator Rubber Granulator

The Vulcanator Rubber Granulator is versatile and suitable for various industries, including:

- Manufacturing: Convert rubber bales into hoses, belts, and other rubber products

- Automotive: Efficiently process rubber waste from tire manufacturing, gaskets, and other automotive components.

- Construction: Repurpose rubber waste from insulation, roofing, and flooring materials

- Sports and Recreation: Recycle rubber waste from playground surfaces, athletic tracks, and sports equipment.

Leading the Way in Rubber Processing

At Franklin Miller, we are dedicated to providing advanced and reliable rubber processing solutions, like our Vulcanator Rubber Granulator. This industry-leading technology is designed to efficiently convert rubber into high-quality granules, making processing and recycling more productive and cost-effective for your business.

The Vulcanator: A High-Performance Rubber Granulator

The Vulcanator is a high-performance rubber granulator designed for efficient rubber processing. Its unique design allows it to reduce rubber bales into small granules with minimal heat generation, preserving the quality of the rubber while minimizing energy consumption.

Customized Solutions for Your Business

At Franklin Miller, we understand that each business has unique requirements for rubber processing. Our team of experts can customize the Vulcanator Rubber Granulator to suit your specific needs, ensuring optimal performance and efficiency in your rubber processing operations.

Choose the Vulcanator Rubber Granulator by Franklin Miller for your rubber processing needs and experience the difference in quality, performance, and efficiency. Contact us today to learn more about our innovative rubber granulation solutions and how they can benefit your business.

Benefits of Franklin Miller's Vulcanator Rubber Granulator

The Vulcanator Rubber Granulator is a pivotal piece of equipment for industries looking to efficiently process rubber. This advanced system is specifically designed to transform large volumes of rubber into fine granules, making it an indispensable tool for manufacturing, recycling and repurposing efforts. Its benefits include:

- Efficient Processing: Quickly reduces rubber into granules.

- Robust Durability: Engineered for longevity and consistent output.

- High Throughput with Low Maintenance: Maximizes productivity while minimizing operational costs.

- Precision Cutting: Ensures minimal heat generation, preserving the quality of the rubber.

This granulator is an essential asset for sectors such as automotive, manufacturing, and construction, aiming to enhance their recycling capabilities and contribute to sustainable practices.

Need Help With Your Rubber Application?

Our engineers have decades of experience solving rubber challenges. Tell us about your process and we'll recommend the best fit.

See It in Action

The VULCANATOR Rubber Granulator

The VULCANATOR® is specially designed for the rubber and heavy plastics industry. This unit has the unique ability to reduce whole 75 lb. bales of synthetic or natural rubber into small particles. The VULCANATOR can handle all types and shapes of vulcanized or non-vulcanized, natural or synthetic rubber including full bales, sheets and chips.

Industries & Applications

Explore Other Industries

Trusted by Industry Leaders Worldwide

Engineering Excellence Since 1918

Let's Find the Right Solution for Rubber

Our team is ready to help you select the right equipment for your rubber application and operating conditions.