Problem: A major New Jersey consumer product company was faced with a problem. Their facility was going to be replaced. The warehouse was filled with damaged containers of detergent that needed to be remediated. The plastic half-gallon containers, in corrugated boxes, along with other miscellaneous materials, such as; wood, glass, and broken pallets had to be safely disposed of before the facility was torn down.

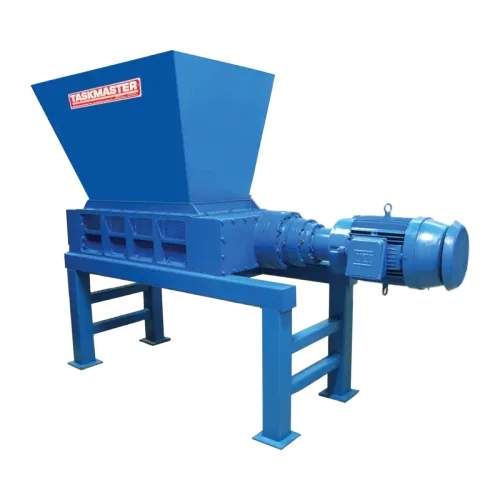

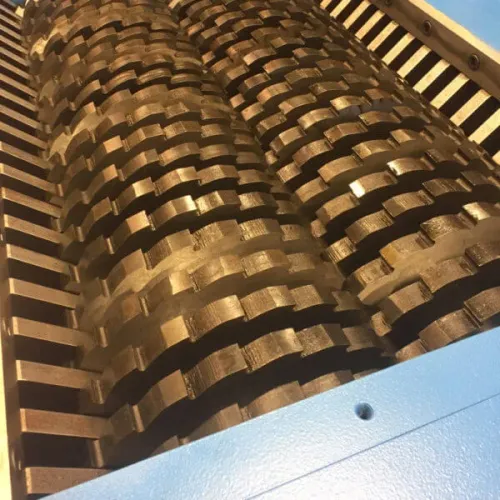

Solution: The company hired an Environmental Waste Remediation organization to properly destroy and dispose of the off-spec product. The fluids in the container had to be safely disposed of without endangering the local sewer system. The off-spec product was introduced into the hopper of the TM2300 shredder by an end-loader. After the material was shredded, the solids were separated from the liquid and disposed of properly.The TASKMASTER® TM2300 Shredder used for the application has a fully enclosed dust-tight body of heavy structural steel. Hardened and ground cutter disks and spacers ride on two parallel hex shafts.

These cutters counter-rotate at differing speeds intermeshing one with another. The exclusive split-body frame design allows easy access to the cutters. This feature allows fast removal of the complete cutter assembly as a whole from the top of the unit.

The powerful TASKMASTER Shredder is designed to shred solid waste in a broad range of applications with minimal maintenance. The TM2300 line of TASKMASTER Shredders successfully reduces bulk up to 80%.