At CRBM Marine Biology Research Center in Quebec, Canada, researchers were in search of a grinder for a project involving marine biomass. A big part of this research project was focused on finding and extracting marine molecules that could fight against major diseases such as cancer (breast, lung, prostatic and intestinal). For the research, marine materials such as hard shells, lobster pieces, stretchable fish skin and even large and resistant seaweed needed to be ground to a homogeneous size so the research elements could be effectively extracted from the material. Getting the output size right was imperative to having a workable material for the very delicate extractions and research.

During the research process, lipids, proteins and other valuable residues such as carbonite calcium, enzymes and other molecules, all extracted from the marine biomass, are used. These molecules are also used for researching and producing cosmetics, natural health products as well as food and vitamin supplements.

When they first began their research, CRBM was using a basic meat grinder. The results were uneven and unreliable and the material frequently got stuck in the grinder and ruined. It was also a slow and tedious process that could not keep up with the demand of the research.

“To obtain the proper molecules for this research, the grinding output has to be perfect in order for the extraction step to work,” said Simon Cartier, CRBM Project Manager and Process Development Research Officer. “There are so many factors that can affect output, so we had to find a machine that could provide the exact size and quality that we needed. The grinding and homogenizing is always the first step in many of our processes, such as hydrolysis, so it is crucial to achieve appropriate grinding in order to obtain the best extraction yield after grinding.”

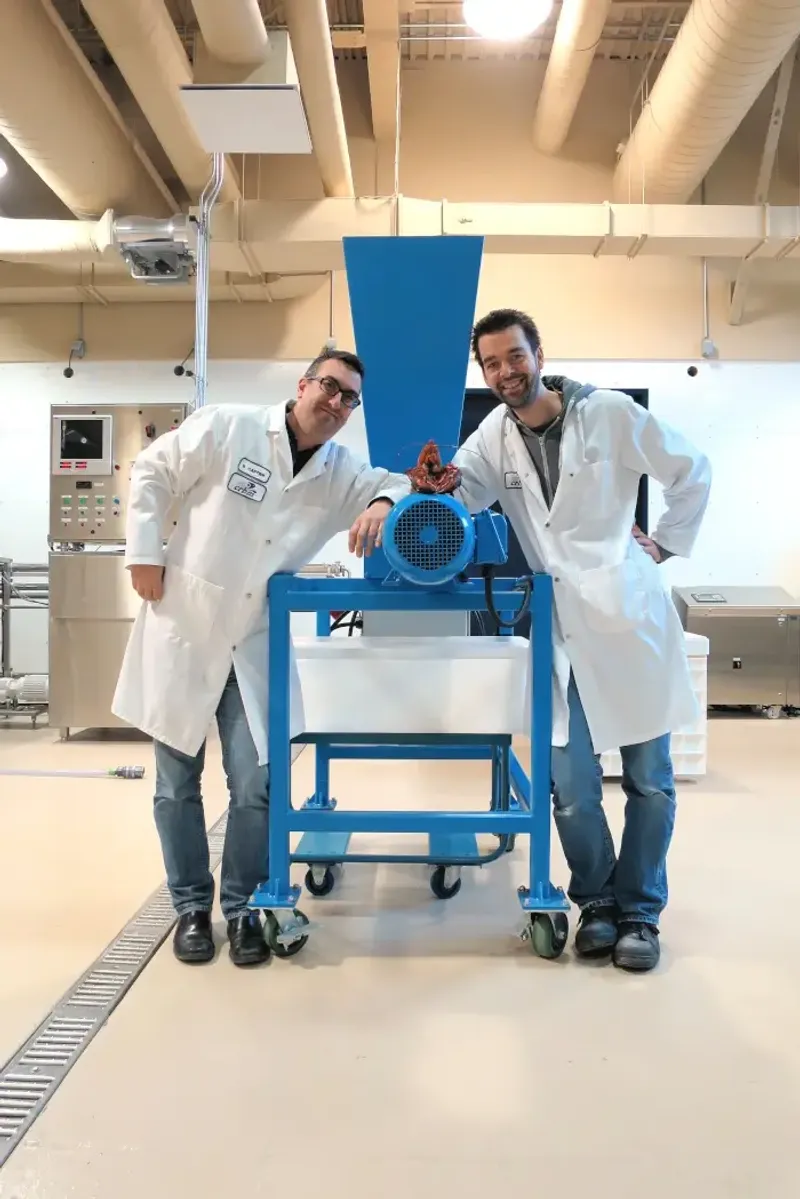

“We looked for a long time to find a grinder that would allow us to crush various marine biomasses and learned about many different options before finding the TASKMASTER®.” When they installed the TASKMASTER in 2015, they expected to have to run the material through 2 or 3 times to obtain the desired output size. Instead, they were happy to find the TASKMASTER gave them the fine homogenous output with a perfect surface size and contact with their material only going through once. “We were shocked and incredibly happy,” said Cartier. “This has taken our research to higher levels much faster. It is a fantastic product for any marine biomass application.”

The TASKMASTER TM8500 is a twin-shaft industrial grinder (a fine shredder) that features an 8.5” wide cutting chamber up to 60” long and a direct drive. It features a fully-sealed housing, mechanical shaft seals and CUTTER CARTRIDGE® technology with unique cutting profiles.

“The addition of the TASKMASTER in our facility was essential. Using the TASKMASTER prior to extraction allows us to easily facilitate the marine proteins and peptides, marine lipids and other types of interesting molecules for our research.”

“We looked for so long and wow, did we find it! What a good choice this was for us. It worked very, very well. We are very happy with it.”

According to Simon Cartier, the company loves their TASKMASTER so much they are spreading the news. They even let another division borrow the TASKMASTER for their own research grinding algae. “Every pilot plant should have a TASKMASTER grinder!”