Super Shredder®

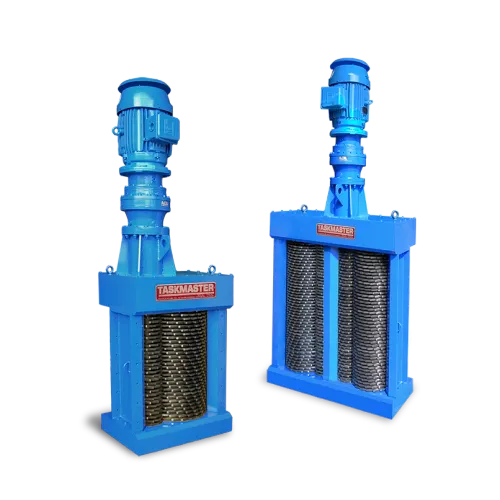

The Super Shredder® is a high-flow inline macerator that uses a spherical rotor design to reduce wastewater solids into fine particles, protecting pumps and downstream equipment.

Key Features

- Reduces Tough Solids

- High-Flow Design

- Spherical Rotor Design

- Stainless Steel Rotor

- Low Speed High Torque

Established 1918 · Made in USA · Livingston, NJ

- SS4-8000

- SS6-800

- SS8000

- SS1000

- SS1200

- SS1600

- SS1800

- SS2400

Product Overview

Benefits and Advantages

- Cutter Technology

- Spherical rotor with intermeshing stationary cutters

- Mounting Options

- Inline installation with 150 lb. flanged connections

- Construction Materials

- Stainless steel rotor with Chrome Boride hardfacing

- Features

- High-flow design, low headloss, efficient solids reduction, minimal maintenance, clog prevention

The Franklin Miller Super Shredder® is a powerhouse in waste management, delivering a multitude of operational benefits:

- Superior Efficiency: Our unique low-speed, high-torque grinding technology ensures swift and thorough reduction of solids, significantly enhancing throughput while reducing energy consumption.

- Advanced Clog Prevention: The spherical rotor design, coupled with precision cutting actions, effectively prevents blockages, ensuring uninterrupted system operation and reducing the need for manual intervention.

- Long-Term Durability: Chrome Boride Hardfacing on the cutting surfaces offers exceptional wear resistance, prolonging the unit's lifespan even in abrasive environments and reducing the frequency of replacements.

- Operational Flexibility: Adaptable to a range of applications, the Super Shredder can process a diverse array of materials, from organic waste to tough solids, without compromising performance.

- Economical Maintenance: Designed with ease of maintenance in mind, the unit allows for quick servicing, minimizing downtime and operational costs.

- Environmental Impact: By enhancing the efficiency of waste processing, the Super Shredder contributes to a smaller carbon footprint for your facility.

- Expert Support: Franklin Miller’s dedicated support team is available to assist with any operational needs, ensuring that your shredder continues to operate at peak efficiency.

- Streamlined Installation: The Super Shredder integrates seamlessly into existing pipelines via standard 150 lb. flanges, facilitating easy and cost-effective installation.

With these advantages, the Super Shredder not only improves the functionality of waste management systems but also contributes to the overall reliability and cost-effectiveness of the operations it supports.

Options

Customize this product for your application

The SUPER SHREDDER utilizes a low speed and high torque action to chop, grind and shred solids into fine bits that can be easily processed by downstream equipment. Its innovative open-center spherical rotor design maintains a high percentage of open area—making this unit practically invisible to the flow. In fact, it can handle higher flows than any other inline grinder available. As the rotating cutting edges precisely intermesh with stationary cutters at close clearance, solids are finely reduced with a scissor-like action. This unique design effectively handles round, even-shaped solids as well as irregular objects.

The SUPER SHREDDER, coupled with Franklin Miller Chrome Boride Hardfacing, makes it excellent for long life in abrasive service.

Dimensions

| Model No. | HP (kW) | Pipe/Flange Size | Flange CL to Base | Flange CL to Top | Overall Height | CL to Near Edge | CL to Far Edge | Overall Width | GPM (l/s) |

|---|---|---|---|---|---|---|---|---|---|

| SS4000 | 3(2.2 kW) | 4″(100mm) | 7.125″(181mm) | 19.5″(495mm) | 41.5″(1054mm) | 3.5″(89mm) | 7″(178mm) | — | 350 gpm(22 l/s) |

| SS4-8000 | 3(2.2 kW) | 4″(100mm) | 8.44″(214mm) | 23.75″(603mm) | 45″(1143mm) | 4″(100mm) | 8″(203mm) | 24″**(610mm) | 400 gpm(25 l/s) |

| SS6-8000 | 5(3.7 kW) | 6″(150mm) | 8.44″(214mm) | 23.75″(603mm) | 49.25″(1251mm) | 4″(100mm) | 8″(203mm) | 26″*(660mm) | 800 gpm(50 l/s) |

| SS8000 | 5(3.7 kW) | 8″(200mm) | 8.44″(214mm) | 23.75″(603mm) | 49.25″(1251mm) | 4″(102mm) | 8″(203mm) | — | 1200 gpm(76 l/s) |

| SS1000 | 7.5(5.6 kW) | 10″(250mm) | 9.125″(232mm) | 25″(635mm) | 52.875″(1343mm) | 8″(203mm) | 16″(406mm) | — | 2200 gpm(139 l/s) |

| SS1200 | 10(7.5 kW) | 12″(300mm) | 11.56″(294mm) | 32.125″(816mm) | 61.5″(1562mm) | 6″(152mm) | 12″(305mm) | — | 3000 gpm(189 l/s) |

| SS1600 | 10(7.5 kW) | 16″(406mm) | 15.31″(389mm) | 40.44″(1027mm) | 69.875″(1775mm) | 8″(203mm) | 16″(406mm) | — | 4800 gpm(303 l/s) |

| SS1800 | 15(11 kW) | 18″(450mm) | 16.75″(426mm) | 42.56″(1081mm) | 74.875″(1902mm) | 9″(229mm) | 18″(450mm) | — | 5700 gpm(360 l/s) |

| SS2400 | 20(15 kW) | 24″(600mm) | 21.625″(549mm) | 55.625″(1413mm) | 91.19″(2316mm) | 12″(300mm) | 24″(600mm) | — | 9200 gpm(580 l/s) |

See It in Action

SUPER SHREDDER Inline Disintegrator

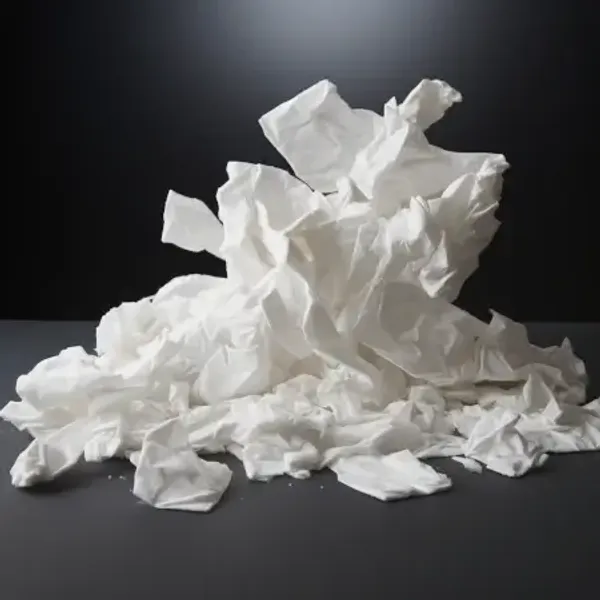

The SUPER SHREDDER easily installs into straight-through pipe systems via 150 lb. flanges. It quickly goes to work reducing solids such as wood, rags, sludge, wipes, paper and plastics. The SUPER SHREDDER stops pumps and valves from ragging and plugging, protects filter presses from expensive punctures and incomplete dewatering and protects centrifuge operation. It can process waste sludge, agglomerates, oil solids, animal waste, paint sludge, pulp and paper, tannery waste, fish scrap, dredge and more.

Technical Specifications

- Cutter Technology

- Spherical rotor with intermeshing stationary cutters

- Mounting Options

- Inline installation with 150 lb. flanged connections

- Construction Materials

- Stainless steel rotor with Chrome Boride hardfacing

- Features

- High-flow design, low headloss, efficient solids reduction, minimal maintenance, clog prevention

Need Help Choosing the Right Solution?

Our engineers have over a century of experience matching equipment to applications. Tell us about your process and we'll recommend the best fit.

Applications & Usage

Where This Product Is Used

More to Explore

Related Grinders

TASKMASTER® TM6500

Interested In Learning More About Our Taskmaster® TM6500?

TASKMASTER® TM8500 Wastewater Grinder

Interested In Learning More About Our Taskmaster® TM8500 Grinder?

TASKMASTER® TM8500 Inline

Interested In Learning More About Our Taskmaster® TM8500 Inline?

TASKMASTER® TITAN

Interested In Learning More About Our Taskmaster® Titan?

TASKMASTER® TM1600 Grinder

Interested In Learning More About Our Taskmaster® TM1600?

TASKMASTER® TM1600 Inline

Interested In Learning More About Our Taskmaster® TM1600 Inline?

Trusted by Industry Leaders Worldwide