Grinders, Shredders and Comminutors – An Evolving Technology

Comminution technology has been evolving quite rapidly in response to the increasing burden entrained solids have placed on treatment facilities. More advanced devices have been developed in rapid succession. The result has been an exciting and fluid race between the leading manufacturers to develop the best size reduction device. The latest grinder innovations to be introduced have coupled the power of twin shaft grinding with higher flow capabilities and screw screening systems. Here’s a rundown on the past and present state of the art in wastewater solids reduction.

Wastewater solids such as tampons, sanitary napkins and plastic laden disposables like diapers and other solids are becoming commonplace in wastewater. Even entire shirts, blankets and uniforms are found in wastewater downstream of correctional and other institutions. Even where screening is employed some percentage of solids remain in the system and often weave into formidable bundles that can ensnare rotary equipment and nozzles. These solids must either be screened or ground to a size that can pass through the system without plugging of equipment

Since the 1950s, each decade has seen the development and installation of a new breed of solids reduction (comminution) devices. Each major new development contributed a set of improvements in performance. Over time many of these units have evolved and found specialized applications where they excel.

Of late, the pace of twin shaft comminutor development and innovation has accelerated markedly. These units use two counter-rotating banks of intermeshing cutters to cut and shred solids to fine particles. The shortfall of these units has been their banks of cutters provided little open area for fluids to pass through. The latest designs discussed below have solved this problem to form a compact solids screening system.

What is a Comminutor?

Comminutors (a.k.a. grinders, macerators) are used to reduce the particle size of wastewater solids. The terms “Sewage Grinder” and “Comminutor” are two terms for a cutting device for sewage solids. The term “comminutor” originated with a device for chopping meat. It was later applied to equipment used for reducing pharmaceuticals and wastewater. The term grinder, as in meat grinder, is commonly used to imply a comminutor that reduces solids finely and often has multitudes of cutting edges. However, this is a loose terminology. There are units that finely reduce solids with only a few working elements. The original sewage grinders, installed as long as thirty years ago, were all called comminutors. Many of these machines are still in service to this day although some are sorely in need of hard to find spare parts. In response to operators’ frustration with these units, manufacturers refrain from calling their current offerings – comminutors. But most persons skilled in this art agree that comminutor is the valid term for this type of device.

Where Comminutors or Grinders are Used

An important use for comminutors (grinders) is in the primary treatment of raw sewage solids in plant headworks and pump stations. Large, stringy solids can easily plug even supposedly “non-clog” pump impellers and necessitate the use of size reduction devices. In sludge, inline grinders are often installed ahead of pumps in recirculation lines and also to enhance the operation of dewatering equipment, digestors and nozzles which can easily become plugged. Belt filter presses and centrifuges are especially sensitive to oversized particles that can puncture filter membranes, reduce their efficiency or damage expensive centrifuge drums. As a result, grinders can easily pay for themselves in damage and downtime prevention.

Comminutors are commonly employed where it is undesirable, impractical or uneconomic to remove solids due to the lack of disposal options. Even when screening equipment is employed, some solids inevitably slip through, so the use of a comminutor is useful as a backup. Alternatively, some plants find it desirable to put the solids through the plants’ digestion processes and thus require size reduction equipment and not screening.

A Brief History of Comminution

Drum Type Comminutors

Sewage comminutors date back to the early 1950s with the introduction of the bottom discharge Comminutor. This unit featured a rotating drum with attached cutter teeth. Solids would get caught on and rotate with the drum and get reduced as the teeth passed through a fixed comb. This design featured a large active screen area and heavy construction. The drawbacks of this unit’s design included: a bottom discharge that required a special “L” shape channel construction; trouble handling certain solids, the rotating drum was subject to wear from bottom grit, and the teeth were extremely difficult to remove to service.

Straight-through Comminutors

Next to be introduced was the Worthington comminutor that fit into straight-thru channels. Its oscillating cutters wipe a semi-circular screen surface clear and sweep and cut the solids against vertically mounted stationary cutters. This design featured easier maintenance and a straight through configuration. The drawbacks were the screens were light and subject to puncturing. The unit was incapable of handling the increasingly heavy solids encountered due to low power and a lack of torque at the end of each stroke. The straight thru comminutor generally had a good reputation when maintained. However, if maintenance schedules were missed, unit performance would suffer.

An improved, higher powered, straight through comminutor has subsequently been introduced with a similar but improved design. It has a heavier solids reduction capability, rotary design as opposed to oscillating and a heavier screen. This unit, the DIMMINUTOR, easily replaces and upgrades older straight through Worthington style comminutors, which are no longer made. It features individually removable and replaceable cutters and a cantilivered design that eliminates the need for bottom seals at the gritty channel bottom.

In-line Comminutors/Grinders

The first machine to address the problems of reducing solids directly inline was the Pipeline Delumper. Originally developed in the 1960’s for the chemical process industry, this pressure rated unit quickly became invaluable to treatment plants. It could reduce heavy solids directly inline and improve flow properties of the system thus reducing maintenance problems for operators. The Delumper was the pioneer inline processor that helped treatment plants with a difficult and previously unsolved maintenance problem.

Dual Shaft Comminutors (Grinders)

After the US Navy in the early 1970s adapted the Pipeline Delumper as the wastewater processor of choice for its frigate fleet, a competing inline comminutor was introduced with a twin shaft design. This unit adapted and miniaturized a German twin shaft solid waste. shredder’s mechanism. Others subsequently also started marketing this design for municipal applications.

Twin shaft grinders use two slowly counter-rotating shafts with intermeshing cutter disks. As one cutter passes the opposing cutter at close clearance it shears solids trapped between the two and passes them downstream. This design provided good dry solids reduction and feeding capability. The design came originally from solid waste shredders with up to 300 hp motors for reduction of everything from steel drums and tires to construction debris. The drawbacks of these miniaturized shredders for liquid waste systems were poor ability to pass liquids. They were also excessively complicated assembly due to the use of multiple individual cutter and spacer disks. Another problem was the possibility of cutter stack collapse and disk cracking as every thin cutter was dependent on every other one for its position in the stack.

Cutter Cartridge Enhanced Twin Shaft Comminutors

An improvement to the original twin shaft design was the introduction of cutter cartridge® elements. These cartridges replace the multiple individual cutters and spacer disks with one piece solid cartridge elements. This increases cutter strength and eliminates multitudes of small gaps and associated stack re-tightening requirements. The cutter cartridge design is often used to retrofit twin shaft units with old individual cutter disks.

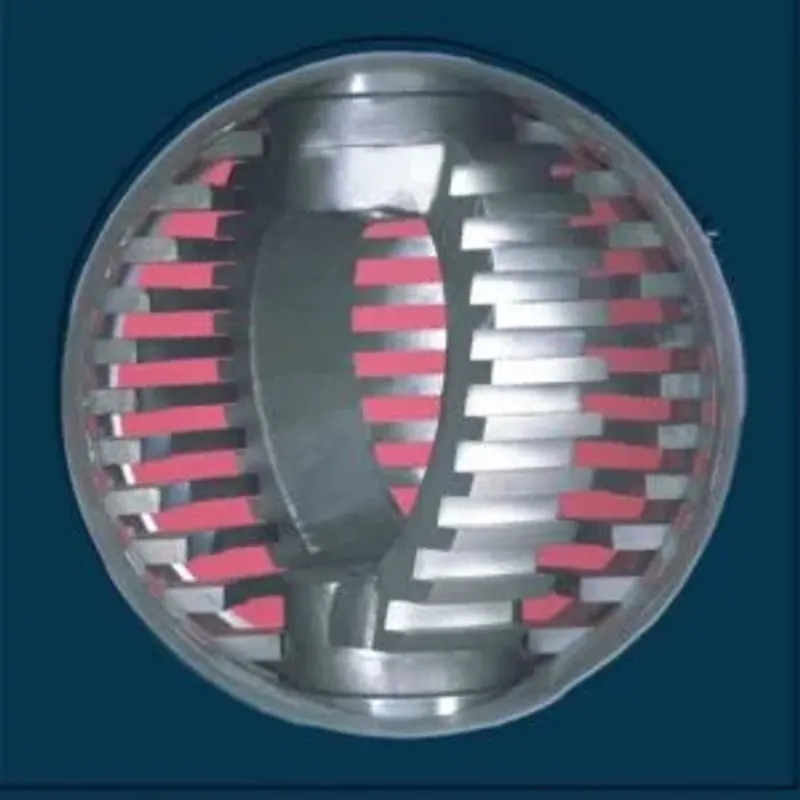

In-line “Shaft-less” Design

The FMI Super Shredder employs a spherical rotor design with a completely open “shaftless” center. It combines the benefits of an open flow configuration for low headloss with a high shear principle that produces a finely ground output. This unit features a bi-directional cutting operation, heavy solids handling, abrasion resistant hardfaced cutters and stainless steel cutter construction. The Super Shredder excels at handling high flow rates with a minimum of headloss. As it only has two cutting elements, it is simple to maintain. The design uses the flow to help in feeding the unit, so it is best applied to applications where the flow velocity is greater than 2 ft/sec.

Hi-Flow Twin Shaft Grinders with Diverters

To improve the flow capability of twin shaft units, various flow “diverters” have been employed to move solids to the grinder while allowing flow to bypass the grinder. The first of these grinders with a “diverter” design was introduced the 1950s by Geiger. This unit employed a grinder unit in combination with a vertical rotating drum screen to handle high flows.

In the later 1980s, the diverter concept was again introduced. Several units implemented flat diverter screens such as the “disc screen” which employed multiple parallel banks of rotating disks to convey solids to an adjacent grinder. Another design re-introduced the drum screen with an adjacent grinder.

While these designs increased the flow capability of their grinders, they also had a number of drawbacks. Flat screen or disc designs were subject to “plastering” or bridging of solids across the screen. Screen wear against bottom grit was problematic. Also, solids tend to get trapped within the screen center. Solids could also bypass the grinder altogether as these units have no way to assure that the solids don’t escape in the gap between the screen and the grinder. In the drum type screen, only 1/4 of the screen can be active as the rest rotates in the wrong direction or doesn’t feed the solids effectively. This results in increased headloss.

Reducing Institutional Waste and Screenings

The units discussed above fall into the category of “grinders” which typically have between a 1 and 5 hp motor. While they can do an excellent job on typical wastewater solids, there are some applications that are better left to a larger industrial strength “shredder”. These are units that typically have a minimum of 10 or 15 hp motors and are built with a heavier drive and shafting to accommodate the added power.

The applications for these shredders include institutional waste where high concentrations of solids are encountered. Often prisoners flush whole bed sheets, blankets and garments into the wastewater system in a deliberate effort to plug the system. The screenings discharged from a bar screen is another case where a heavy duty 10 or 15 hp shredder is suitable. While grinders excel at handling liquid-borne solids, heavier solid masses which are not suspended in a liquid carrier call for a heavy duty shredder type device.

The Latest Developments

The latest innovations in twin shaft channel grinding, the Taskmaster TITAN, feature new designs that handle higher flows than and avoids the pitfalls of the previous units as well.

Twin Shaft Grinders Using Two Cutter Diameters

Another recent improvement in high flow grinding is the Taskmaster Titan. This unit employs twin shafts with intermeshing cutters but each stack has a different sized cutter disks. The benefit of this design is that the smaller disks efficiently perform the cutting against an apposing cutter disks while the larger disk allows much more fluid to pass through. The result is a twin shaft grinder that requires no more power than previous units but handles much higher flows without the need for diverter screens and their potential operational problems. It can also more effectively feed larger solids into its cutters without repelling them.

Some Grinders Can Screen Too!

The addition of a shaftless screw-screen behind the discharge of an in-channel grinder results in an interesting synergy. The screw screen becomes more effective at removing solids from the flow and the ground solids are more easily washed and compacted. These combined grinding and screening systems have been introduced by two manufacturers and have proven to be an effective alternative to bar screens. One manufacturer employs the Titan style grinder where the larger cutter acts as a primary screen for enhancing the system’s flow capability as compared to a screw screen alone. The second manufacturer uses their rotating diverter screen for the same purpose.

Things to look for when selecting a grinder:

- Is the manufacturer well established and have broad experience in the field?

- Is the unit ruggedly constructed

- Will the design handle the present and future flow capacity without excessive upstream head?

- Is the design easy to maintain in the given installation?

- Is the unit built for long term reliability and ease of maintenance?

- Is the unit built with materials that are resistant to the corrosive or abrasive conditions of our flow?

- Is the unit capable of handling the specific solids encountered in your system such as industrial waste or institutional solids such as particularly heavy solids encountered downstream from correctional facilities.

An important criteria in choosing a grinder is hydraulic performance. Can the unit be placed in the flow without raising the head excessively to the point of backing up the system or cavitating the pump? For this, it is important to work closely with the manufacturer in sizing of the unit to the application. In general, a more open design will pass more flow and cause less backup than a unit with a higher percentage of closed area.

About the Author

William Galanty is a holder of 10 patents in the field of wastewater comminution and is the President of Franklin Miller Inc., a manufacturer of size reduction processors for municipal as well as industrial applications. He is experienced in the design and application of high powered industrial solid waste shredders, design and production of high pressure and complex industrial size reduction systems in addition to his experience in wastewater treatment comminution. Mr. Galanty has also testified as an expert witness on the design and application of wastewater grinders.

Interested In Learning More About Our Wastewater Grinders?

Contact UsEngineering Excellence Since 1918

Need Help With Your Application?

Our engineers have decades of experience solving complex processing challenges. Let us help with yours.