Size Reduction Paradox

Excellent Equipment Is Being Designed In Spite of the Lack of a Single General Theory HAROLD E. GALANTY

Franklin Miller Inc.

Literature on size reduction is plentiful and several useful “laws” are available, but a` single generally acceptable theory has not been formulated. The frame-work is complex and promises to be more complex in the future.

We are told that size reduction equipment is grossly inefficient, theoretically, and that less than 2% of the energy supplied appears as increased surface energy in the solids. Are there thermodynamic or other reasons for this? If the figure is accurate, then, can revolutionary types of equipment be designed? At least one author thinks not (16).

In the meantime, excellent equipment continues to be designed and put into service for every type of solid and semisolid. Designers are constantly improving equipment and standard data can be extrapolated to specify equipment for most uses.

Material Characteristics.

Solids differ in the mechanism and form fracture. Also, they differ in properties-they can be weak, strong, and soft or hard, as defined by Young’s modulus, and any combination of these conditions can be met in practice. Figure 1 provides considerable data on mechanical, properties and behavior.

The first straight line part of the curve follows Hooke’s law- i.e., stress is proportional to strain, and the ratio of stress to strain (modulus of elasticity) measures stiffness or softness in pounds per square inch or dynes per square – centimeter.

Stress at the knee of the curve is the first yield point which measures resistance to permanent deformation. Beyond this point is the failure region where plastic

deformation for the most part is not recoverable. The maximum or ultimate strength is that required for fracture, and total area under the stress strain curve represents the energy required for such fracture (Figure2). This area is also a rough measure of toughness or impact strength.

When stressed beyond their elastic limit, ductile materials retain strains, even after the stress is completely removed (Figure 3). The stress-strain curve returns to a new point of permanent elongation, rather than to its origin, and the difference in area between the two curves is retained strain. When the material is reloaded, it follows Hooke’s law to a higher yield point in the plastic region, but approximately on the original curve. This phenomenon, called strain hardening, does not affect greatly the ultimate strength and the true stress at fracture.

Except for permanent strain, it has been assumed to this point that the stress-strain curve in the elastic Hooke’s law region is reversible–i.e., the curve for unloading is the same as that for loading. Materials such as steel follow this pattern closely, but for most others such as high polymers, particularly rubber, hysteresis is common (1): If the material is unloaded and then reloaded, the original permanent set returns eventually, but an elastic looping or hysteresis of the strain cycle occurs. The area of this loop represents the energy dissipated per cycle, which usually appears as heat. As the stress goes through the cycle, strain deformation lags in time, resulting in net work input and heat loss.

Energy is lost by hysteresis also (caused by phase non-equilibrium) in crystallization of amorphous materials during distortion. Another is a possible Carnot-cycle hysteresis from an entropy factor in thermal non-equilibrium at some step in the deformation process. This can result if a solid is deformed adiabatically and returned isothermally, or vice versa (1). The free energy increase on distortion caused by entropy decreases results in an exothermic action. Other elements of dislocations in hysteresis can be treated more extensively (23).

The peak stress of impact loading (loads applied suddenly) is always higher than that for loads slowly applied. Relative impact resistance can be determined by the Charpy and Izod tests, but the quantitative significance is disputed. For impact loading, it is not certain that the total area under the stress-strain measures energy to fracture.

It is usually assumed that rubber-like materials have high impact strength, and hard materials are likely to be brittle. But the load deformation depends upon rate of loading. Some materials are flexible under slow application of load, but under rapid impact the flexibility may be retarded, resulting in much steeper deformation curves and failure in brittle fracture (1). On the other hand, for certain brittle materials, the slower the rate of loading the lower the fracture stress can be (19,21).

Hardness measures resistance to deformation (4). This is usually expressed in the Moh scale by scratch test in which the diamond has a scale of 10 and talc a scale of 1. In penetration tests of the Brinnell or Rockwell type, the specimen is indented plastically by an indentor of known dimensions and measured load.

Brittle State. Whether a material is brittle or ductile may depend on temperature and other factors (24). A brittle material fails only in tension. The fracture shatters suddenly because no plastic deformation slows the crack propagation or limits the stress. Cracks proceed rapidly as radiants of fissures are developed.

Brittle materials may have high modulus elasticity and tensile strength, but a high modulus does not necessarily imply high strength. However, if the tensile strength is low, the brittle material is considered friable.

Crystalline materials such as sodium chloride brittle- fracture along crystallographic cleavage planes, usually in the same plane as is prominent in normal crystal growth (19). Below their softening point, non-crystalline materials such as glass fracture at random through the solid, usually with conchoidal (shell-like) fracture surfaces (29). A hackly fracture surface indicates an extremely violent and sudden parting, while a smooth, bright fracture is one which occurred more slowly (21).

The strength of brittle materials is a statistical quantity varying over wide limits (15) .The published values are mean values arrived at by taking into account the scatter of strength data. The statistical nature of brittle strength is such that larger volumes of brittle materials can exhibit lower relative strengths than smaller volumes. Weibull (19, 30) derived the rupture probability, R, assuming, it to be a function of both volume and tensile stress:

He concluded that where is usually published strength; characteristic strength depending on distribution function fitting the data; and m, degree of homogeneity (larger m is for increasing homogeneity).

Brittle fracture is successfully explained by the Griffith theory of cracks and flaws (15) which has been verified by experiment and microphotographs. All solids contain small, usually microscopic cracks normal to the applied stress which are efficient levers for prying solids apart. The crack multiplies the characteristic strength depending on the applied force by an amount increasing with crack length, focusing the stress at the atomic bonds of the crack vertex (14). Also, defects in the atomic lattice of a crystal grain can cause cracks. Even in rubber-like substances, brittle fracture can occur, as the result of crystallite development under stress (1, 28).

The Griffith theory of brittle fractures as modified (22, 23) is summarized:

where σ is tensile stress; E, Young’s modulus; γ , surface energy of walls of the crack; and c, critical crack depth required for fracture.

Ductile State.

A ductile material fails as a result of shear following continual thinning and breaking down. It is a mor egradual process than brittle fracture (19), and fracture strength, unlike that of the brittle state, is reproducible within narrow limits. The fracture starts at the plastically deformed neck and cannot choose the worst of the flaws which may be present.

In materials having slight ductility, there is considerable work of plastic deformation at the advancing crack tip. In tougher ductile materials, greatly increased stresses are required to keep the fracture moving through the material. New cracks must be nucleated as the fracture passes each phase boundary.

Ductility is the result of the plastic flow caused by many crystal dislocations sliding over atomic slipplanes. Inherent defects play only a secondary role in the fracture (23). The cracks which lead to fracture are caused by the plastic deformation itself. Crystalline edge dislocations piling up in front of a hard inclusion can cause this. Or, a row of edge dislocations can produce the high stresses as they approach one another (23).

First advanced on a theoretical basis, dislocations were later discovered in real crystals and call be observed by various techniques The dislocations are regions in which the atoms of the crystal are not lined up in perfect array. Part of the crystal contains all extra plane of atoms which has slipped a distance of one atomic spacing over the balance of tile array. Another way of looking at it is that the dislocation consists of a single line of atoms having one less atom coordinating it than the normal coordination for the crystal structure.

At the edge of the dislocated plane there are atomic seconds which are stretched and distorted. This is the edge dislocation. An edge dislocation yields more easily to a shearing stress than a perfect crystal, which explains why crystals deform along individual glide planes (Figure 4).

A second kind of dislocation is known as the screw-type which consists of a line of atoms each having the correct number of atoms in coordination. Two parts If the crystal are slipped parallel to the line of dislocation, creating a spiral ramp winding through the crystal around the dislocation line at the center (Figure 5). By using various etching and decoration procedures, the dislocations can be photographed.

The two types of dislocations described are only limiting cases. The dislocation line can assume various angles with respect to the atomic displacement (70). These angles are indicated by the Burgers vector parallel to the screw location. According to Orowan (23), the energy required for plastic deformation is:

Where Γ is the specific elastic distortion energy per interatomic spacing; b , inter-atomic spacing; and E , Young’s modulus.

Crystals can also deform by forming deformation twins. In this twinning process two parts of the crystal are displaced so that they appear to be mirror images. There are critical stress values for twining as there are for slip and for fracture.

Crystallization of Amorphous Polymers.

Many materials, such as natural rubber, which are considered to be amorphous, will develop crystallites under strain at ordinary temperatures (1, 28). This is a definite change in structure as indicated by x-ray, diffraction composed of brittle elements. If a crack occurs in a brittle element, it is isolated from the others patterns. The crystallites are embedded in an amorphous matrix, and are much more rigid than the amorphous material. They act as rigid inclusions in the plastic matrix. The effect results in an increase in the elastic modulus. A two-phase structure is created from an apparently homogeneous material (26).

Two phase materials are essentially a combination of a brittle substance of relatively high strength and high elastic modulus in a matrix of relatively low elastic modulus ductile material. It may be homogeneous such as the crystallized rubber mentioned previously, or it may be a mixture such as glass-filled epoxy resin. These materials exhibit the properties of a tough ductile substance of high strength even though partly composed of brittle elements. If a crack occurs in a brittle element, it is isolated from the others by the ductile material so that the crack does not readily propagate (26).

The brittle point is the transition temperature from rubber-like to brittle state. The elastomer becomes both stiff and brittle. The elastic modulus and plastic viscosity become so high that deformation cannot occur quick enough to prevent stresses from exceeding the fracture point (1). The brittle point for un-vulcanized natural rubber, for example, can occur at -70. For pure polystyrene it is as high as 81. Where it is more properly called the softening point. X-ray diffraction patterns indicate that the structure of the ‘material is the same in both states (28)

Surface Energy

Specific surface energy γ is expressed as ergs per square centimeter. In a liquid the surface tension in dynes per centimeter is numerically equal to the surface energy. This does not necessarily hold for a solid. If atoms can diffuse to the interface fast enough as the area is increased, then the surface tensions and surface energies can be almost equal. This is trite at high temperatures for solids having a disordered atomic interface and an ordinary large angle grain boundary. At low temperatures or for low angle grain boundaries this will not hold (20). a solid. If atoms can diffuse to the interface fast enough as the area is increased, then the surface tensions and surface energies can be almost equal. This is trite at high temperatures for solids having a disordered atomic interface and an ordinary large angle grain boundary. At low temperatures or for

low angle grain boundaries this will not hold (20).

The surface energy is probably a complex quantity differing in magnitude with crystal orientation. Methods exist that are potentially capable of determining the magnitude of the surface energy directly but with uncertain accuracy (20). If it is assumed that the surface energy behaves similar to that of surface tension, there might be two values of surface energy. One would be the dynamic or instantaneous value of freshly formed surfaces, which is always higher than the equilibrium static values (21).

If the specific surface energy is γ then for the same piece at moment of fracture the surface energy must be 2γ to provide for the new surface created (19). In other words, the total energy of the surface of the solid should be a direct function of the surface area. The surface energy is there by theorem. It is the starting point for the derivation of the Griffith theory of brittle fracture and is basic to all discussions in the solid state. Yet, information on the quantitative value of the surface energy is scarce, and not fully understood.

The elastic energy corresponding to the stressing of the interatomic bonds is the tensile stress. For brittle fracture to occur, this energy must equal the total energy of the new surfaces formed at fracture. The surface energy is that of the interface solid-air at ordinary temperature. No known method of measuring the surface energy at the interface solid-air is certain. Extrapolations from surface tension values at temperatures for which it can be measured are not justified (21).

Laws of Size Reduction

The laws of size reduction in general use today include those of Rettinger (25), Kick (18), and Bond (7). These laws have been found useful within their limited range of application. The Rettinger and Kick Laws are said by Heywood (16) to be compatible because the former relates the energy required for the reduction to the new surface produced, whereas the latter relates it to the volume or weight of the particles. Many other theories can be found in the literature.

Coulson and Richardson (9) have shown that all three laws derive by integration from the same differential equation; dW/ dL = CI?. That is, change in energy per unit change in size. The exponent P is – 2 for Rettinger‘s Equation, -1 for kick’s, and -3/2 for Bond’s.CI

For fine grinding of brittle materials, where the increase of surface per unit of mass is large, Rettinger’s equation, law has been favor. It is the basis for the Hargrove, machine grindability test (2) wherein the sample receives a definite amount grinding energy surface is determined by sieving. Rettinger’s energy, W, required for grinding may be determined by W = (R – 1)/ where W total energy required for size reduction; K r strength L1, L2 initial and final dimensions of the particles; and R, size reduction ratio, L1 / L2.

For coarse crushing Kick’s law has been favored:

Where k k constant. The energy obtained from this equation id s function only of the size reduction ratio and does not depend on the initial or final sizes. Bond has compromised to some extent to make his law applicable to both coarse and fine grinding (5):

Where W i is the bond work index:

Limitations of the Laws

Numerous tests are reported supporting or disproving one law or the other until there-is considerable confusion (5). The laws have been attacked on theoretical grounds. Some authors state that while Rittinger’s theory, for example, seems logical, a real test of its applicability has yet to be satisfied. Yet, for others the applicability seems to have been demonstrated as in the grinding of coal samples (2), and in the test grinding of phosphate rock (8). The laws seem suited for only specific applications which should be determined by the user. Much more remains to be done on a scientifically acceptable general law of size reduction.

Energy Requirements

Upward of 100 to 1000 times more energy is consumed in size reduction operations than is predicted from theoretical considerations based on surface energy. This may result from large errors in the values of surface energy about which little is known, even for common solids. The tests themselves may be faulty (5).

In any practical size reduction apparatus the actual energy of fracture is only a small difference figure which can account for large discrepancies in energy tests.

The bulk of the energy can be accounted for by

- Efficiency of motor and transmission.

- Efficiency of motor and transmission.

- Friction between particles

- Friction between particles and machine elements

- Windage losses

- Noise

- Heat

- Vibration

- Hysteresis losses of unfractured material

- Strain energy of unfractured material

- Energy of transport of material within the equipment (lifting, etc.).

- Energy of fracture itself

Low utilization of energy on a theoretical basis may be significant in equipment design, but for users, this often is unimportant. Total power required may be quite small compared to benefits derived from the size reduction operation.

Effectiveness of equipment can be related in terms of the input energy per unit of surface produced (16), this is obtained by measuring the input energy in foot-pounds per pound of product, and obtaining the specific surface in square feet per pound using one of the known methods. In practical work the machines are often rated in pounds per horsepower hour.

The energy required is a function of the input and output particle sizes as well as hardness, ductility, strength, density and other properties of the material. In practice, the specified capacity and feeding efficiency may enter into this. In addition, there is a maximum input size which can be fed to the machinery to obtain optimum efficiency. For feed sizes larger than this optimum, the efficiency of the equipment may decrease rapidly, requiring an additional stage of size reduction such as a pre-crushing operation.

Particle Size Distribution

Most common materials have small interlocking crystals or grains at random orientation (4). The size and distribution of these significantly influences the particle size obtained from size reduction equipment. For any crystallized state there is a range of grain sizes within the material which is natural for the conditions of crystallization.

The distribution of particles after size reduction is the cause of great concern. Often, the desired sizes are those which are missing or very difficult to obtain, whereas finer and coarser sizes are evident. Undesirable sizes, particularly finer sizes, are often obtained when coarser ones are preferred. Much of this can be explained possibly in terms of the natural grain sizes within the solid, because these natural sizes tend to come out during the size reduction operation. Reduction of the larger particles may cause desirable in-between sizes to degrade. However, fines can be controlled by clearances within the equipment, and speed and the retention time. This means that a minimum of excess energy should be applied to the material.

According to Heywood (16), Bennett has derived that from a single lump of brittle material the fraction of material smaller than a given size bears a simple exponential relation to the size, which can be expressed:

Where Q is fractional quantity smaller than a selected size, L; e, the base of the Napierian logarithm, 2.718; and Lm mean size of particles in the size distribution.

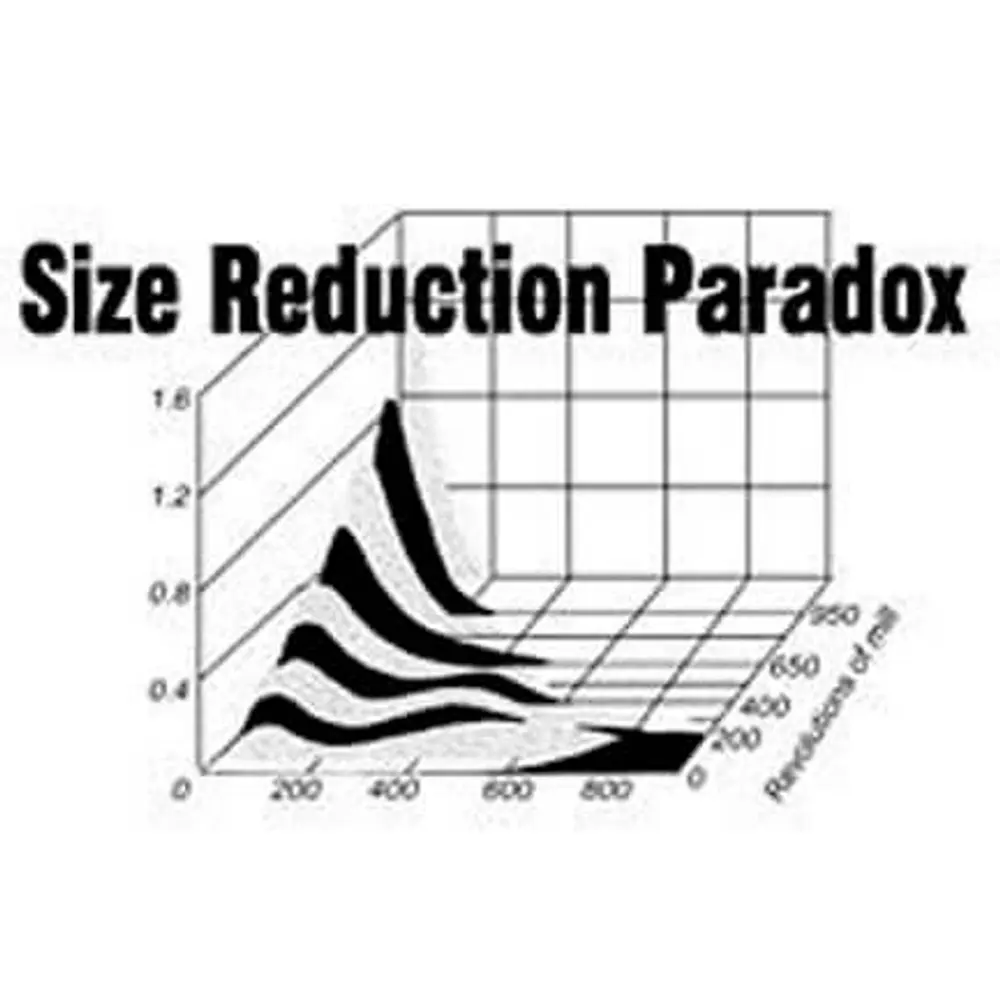

The results of size distribution tests can be plotted as a cumulative undersize weight fraction vs. size (9). From the cumulative data it is often desired to plot a size frequency distribution curve showing the apparent per unit amount of material at each size. This is obtained by plotting the slope of the cumulative curve against size (Figure 6). The cumulative curves when plotted logarithmically are close to a straight line. The size frequency curve rectilinearly plotted will show a normal curve with a maximum mode. For mixed materials and for size reduction equipment having a particular sizing influence, there may be two or more modes. Continual reduction in the same apparatus tends to reduce the first (relatively coarse) transient mode toward a constant mode at much finer particle size characteristic for the particular equipment (Figure 7).

Temperature Rise

Often, the temperature of heat-sensitive materials must not rise above a critical level. In materials such as some waxes, chocolate, cocoa butter, paraffin, and many resins, the temperature limit is quite close to normal room temperature. The less energy put into the solid the lower will be the temperature rise which results mostly from friction between particles, and also between particles and the machine parts. Choke feeding causes particles to rub together more intimately, increasing temperature above that obtained for free feeding. For the same reason, excessively high heads of material increase the pressure and therefore the frictional energy. Excessively high rates of force application cause high, hot-spot temperatures. Some of the excess force is converted to kinetic energy which must be dissipated by impingement friction by the particles. Imperfect application of forces by non-positive means can result in particles remaining unreduced in size but going through a hysteresis energy cycle with resultant heat rise.

Method of Force Application

According to the theory of the solid state, only tension or shear, and not pure compression, can cause fracture. However, we know that forces can be applied as compression, tension, shear, impact, and attrition. In practical equipment there is usually more than one of these forces acting on the material, although one may be predominant.

Tension is the cause of fracture in brittle materials, yet no practical size reduction equipment applies a primarily tensile force. Brittle materials such as salt, limestone, glass, or phenol formaldehyde, when subjected to compression in a double roll crusher or in a jaw crusher, apparently fracture in tension. But the results obtained in compression apparatus can differ from those of tensile tests. Many ductile materials are tougher in applied compression than in tension. Some materials which are brittle in tension, such as unmodified polystyrene, are tough in applied compression (7) with higher yield points and great elongation. Compression-type equipment is easily applied to brittle substances but must be more carefully applied to ductile and soft materials to avoid flattening or compaction. Shear forces can be introduced by compression-type equipment such as roll mills by causing one roll to revolve at a different speed from the other.

Attrition means to rub. But the attrition-type mill such as the double disk burr mills seems to work by shear. The particles are trapped in the; voids of one attrition surface plate and sheared by the projections on the other surface. The large number of projections quickly reduces the particles trapped between the plates to desired size. Various effects can be obtained in the finished product dependent on the pattern of the attrition disk surface.

Shearing action is prominent in cutting and chipping machines such as rotary knife cutters, saw tooth crushers, guillotine cutters, toothed roll crushers, wax chippers, wood chippers, dicers, and slitting equipment. These machines have a number of knives or blades which move, sometimes close to stationary bed knives, sometimes with a screen in close proximity to the path of the rotary knives-to retain the material until proper size is reached. Cutting is regarded as shearing, even if the forces are compression applied at a line by an edged tool.

Impact force -e.g., in hammer mills-increases stress more than slower or static loading. The pin disk mill and the self-bombardment mill depend on impact forces to a great extent. In fact, impact is present to some extent in most types of size reduction equipment. It can be either useful or harmful.

Factors Affecting Efficiency.

In the process industries, materials reduced in size may range from as low as 10 pounds per cubic foot to as high as 300 or more. This factor is important in determining the feeding efficiency, loading within the equipment, .and production rate. Materials with low bulk density compared to specific density obviously have a great number of voids. The equipment naturally can do no useful work when the voids appear, thereby reducing utilization efficiency. Usually the higher the density the greater the production rate.

Other factors influencing capacity include the number of cuts or strikes per minute, effective open area of the system, and feeding efficiency. These in turn are functions of material properties such as strength, hardness, stickiness, and ductility

Also, initial dimensions of the feed influences greatly utilization efficiency. There is, of course, a maximum and minimum size which the equipment can accommodate efficiently. For the least capital investment, equipment must be used close to its maximum production rate. For this, pre-crushing is sometimes necessary

Fracture stress of solids varies with percentage and type of moisture in contact (5). Some materials which decrease in strength with increased moisture reverse the trend after a certain percentage is reached, and become stronger when wet. In general, however, increased moisture beyond a critical level lowers efficiency (2).

Soft, mush-like, clay-like, and waxy materials can be reduced in size, including materials with high moisture content such as filter cake. This is done in minimum energy equipment which chops the material without working it too much. For low average molecular weight materials, the mechanism of rupture seems to be based on viscous flow (13). In other materials fracture in shear is found. Both natural and synthetic wax-like materials and paraffin are regularly handled in specialized equipment.

A problem encountered in size reduction is de-agglomerate lumps or caked materials (8, 17). At high temperatures, the lumps will have an especially hard set with strengths up to 2000 p.s.i. In ammonium nitrate, for example, storage above a 32°C transition point can lead to excessive caking. This problem is found in many materials, and the size reduction equipment used should be able to take large lumps with a minimum of over grinding.

Interested In Learning More About Our Size Reduction Equipment?

Contact UsEngineering Excellence Since 1918

Need Help With Your Application?

Our engineers have decades of experience solving complex processing challenges. Let us help with yours.