Interested in Learning More About our Biomass Processing Equipment?

Biomass Grinders

TASKMASTER® twin shaft grinders play a key role in the primary reduction of biomass solids prior to their transfer to a digester. TASKMASTER grinders and shredders can handle a wide range of material utilized in biogas production.

3

Products

Since 1918

Established

Made in USA

Manufacturing

Livingston, NJ

Headquarters

Taskmaster Grinders

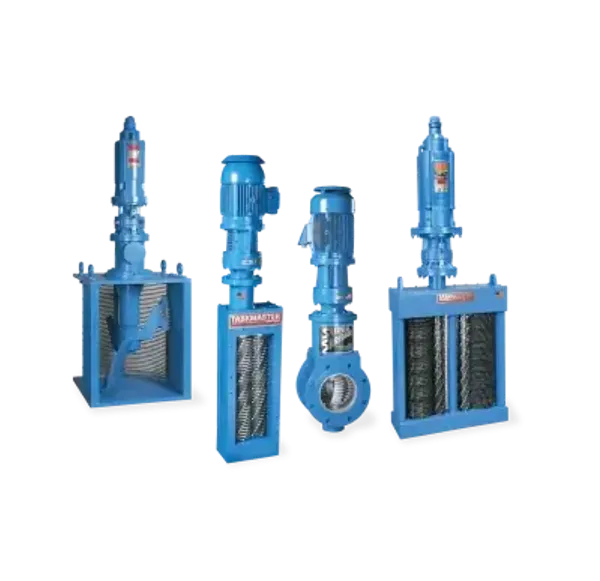

TASKMASTER inline grinders employ a powerful twin-shaft mechanism and CUTTER CARTRIDGE® technology to reduce solids in pipeline systems. Two stacks of intermeshing cutters aggressively pull the solids in and finely reduce them. These grinders can be installed in gravity or pressurized, vertical or horizontal pipe systems, on the suction or positive side of a pump. The TASKMASTER is provided with CUTTER CARTRIDGE® technology wherein 6 cutter disks and 6 spacer disks are replaced by one-piece elements for far greater strength, fewer components, no stack loosening or stack re-tightening requirement.

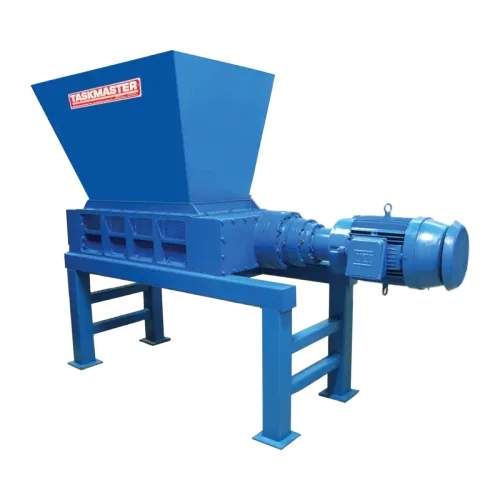

The TASKMASTER® TM1600 industrial shredder is a powerful workhorse that can shred heavy solids in both gravity and liquid systems. This unit can be installed horizontally with a stand, or vertically with a hopper for channel or pipeline applications with flange adapters. The TM1600 industrial shredder features a fully sealed body housing with 2-3/4″ hardened hex shafting, mechanical seals and direct inline or optional right angle gear drive. Options include: stainless steel construction, enclosed hopper, flange adapters, channel frames, infeed conveyor, discharge washer or compactor, hydraulic drive, space saving right-angle gear drive and more.

Franklin Miller TASKMASTER® grinders set the standard for effective solids reduction, reliability, easy maintenance and exceptional durability.

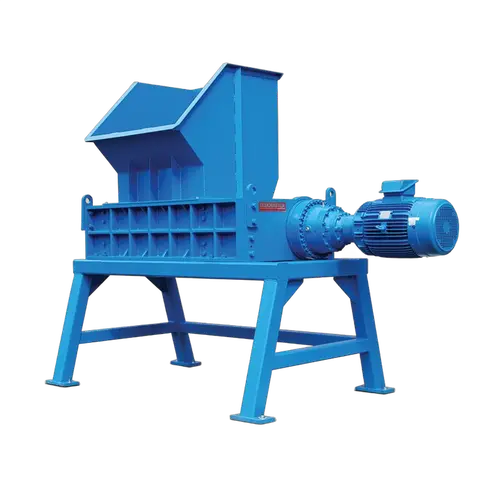

Twin Shaft Grinders

TASKMASTER® twin shaft grinders play a key role in the primary reduction of biomass solids prior to their transfer to a digester. TASKMASTER grinders and shredders can handle a wide range of material utilized in biogas production including plant and food waste, household waste, sludge and much more. These flexible units can be used for both inline and hopper fed applications.

TASKMASTER® TM8500 twin shaft grinders provide unsurpassed grinding of solids, with design features that make them truly unique. These units have proven their capability and unique reliability in installations worldwide. These TASKMASTER grinders feature dependable mechanical seals in a cartridge design and CUTTER CARTRIDGE® Technology.

Biomass

Biomass is plant or animal material used for energy production, heat production, or in various industrial processes that use raw material of and for a range of products. It is often comprised of wood or forest residues, purposely grown energy crops, waste from food crops, horticulture, food processing, animal farming, or human waste from sewage plants. These natural materials have used the sun’s energy in the photosynthesis process to make their own food, which is stored in the plants as chemical energy. When the plants die, this chemical energy is trapped in the residue of the plant. The release of this trapped energy can be converted into biomass energy and biomass fuel, a renewable energy.

Biomass energy can be produced in two ways, either through anaerobic digestion process or through burning.

When waste is processed by anaerobic digestion, microorganisms break down or eat organic materials in the absence of oxygen. The remaining material is called digestate, which is a wet mixture that separates into a liquid and solid. During this process, biogas, a renewable energy source, is generated.

The other common option for biofuel production is through burning, usually done in furnace-style equipment.

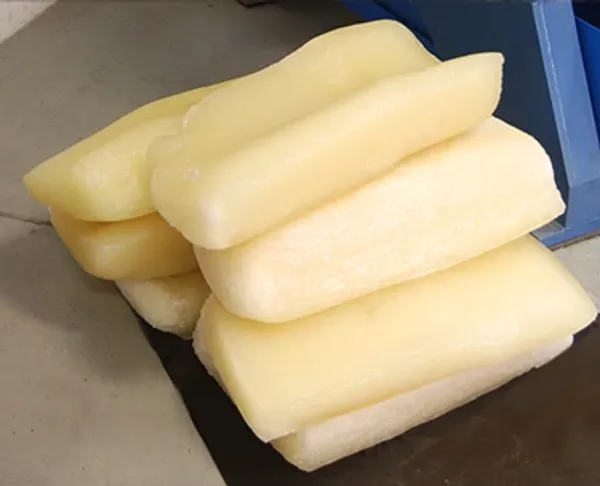

Regardless of the choice of biofuel production, the material needs to be processed and shredded down to a small size in order to be further processed. With the use of a Franklin Miller TASKMASTER® shredder or grinder, the material will be easily cut down to size and ready for the next step in biofuel production.

Need Help With Your Biomass Application?

Our engineers have decades of experience solving biomass challenges. Tell us about your process and we'll recommend the best fit.

Industries & Applications

Explore Other Industries

Trusted by Industry Leaders Worldwide

Engineering Excellence Since 1918

Let's Find the Right Solution for Biomass

Our team is ready to help you select the right equipment for your biomass application and operating conditions.