Interested in Learning More About Our Wipes Grinders?

Wipes Grinders

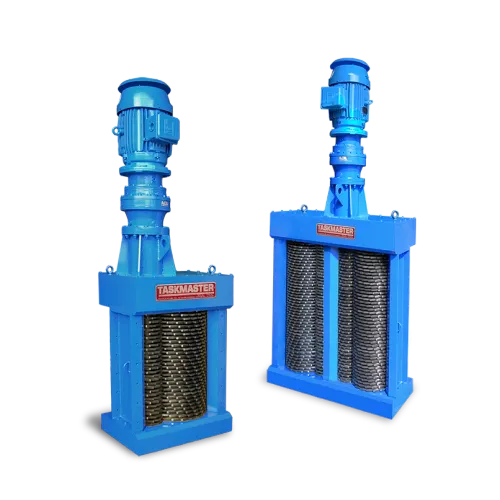

Franklin Miller offers Wipes Grinders specifically designed to address the challenges posed by "flushable" wipes in wastewater systems. These wipes, unlike traditional toilet paper, do not disintegrate easily and often lead to clogs and operational difficulties in pumps and sewer lines. Our grinders are engineered to mitigate these issues, reducing downtime and associated costs for municipalities. With a variety of configuration options such as inline and flange-to-flange installations, as well as the availability of submersible motors, these grinders are adaptable to a wide range of wastewater treatment environments.

5

Products

Since 1918

Established

Made in USA

Manufacturing

Livingston, NJ

Headquarters

Wipes Products

TASKMASTER® TM8500 Wastewater Grinder

Interested In Learning More About Our Taskmaster® TM8500 Grinder?

TASKMASTER® TM8500 Inline

Interested In Learning More About Our Taskmaster® TM8500 Inline?

Super Shredder®

Interested In Learning More About Our Super Shredder® Grinder?

DIMMINUTOR® Grinder

Interested In Learning More About Our Dimminutor®?

TASKMASTER® TITAN

Interested In Learning More About Our Taskmaster® Titan?

Configurations

Our Wipes Grinders are engineered to meet a diverse range of operational requirements. For installations constrained by limited spatial availability, we offer an inline configuration that seamlessly integrates into existing pipeline systems. For more extensive pipeline networks requiring robust interfacing, a flange-to-flange installation model is available, designed to streamline both integration and subsequent maintenance procedures. For applications that necessitate frequent servicing, the grinders can be equipped with guide rails to facilitate easy removal from manholes. Additionally, we provide units with submersible motors to accommodate scenarios requiring underwater operation. This array of configuration options ensures optimal performance across a wide spectrum of wastewater treatment environments.

Problematic

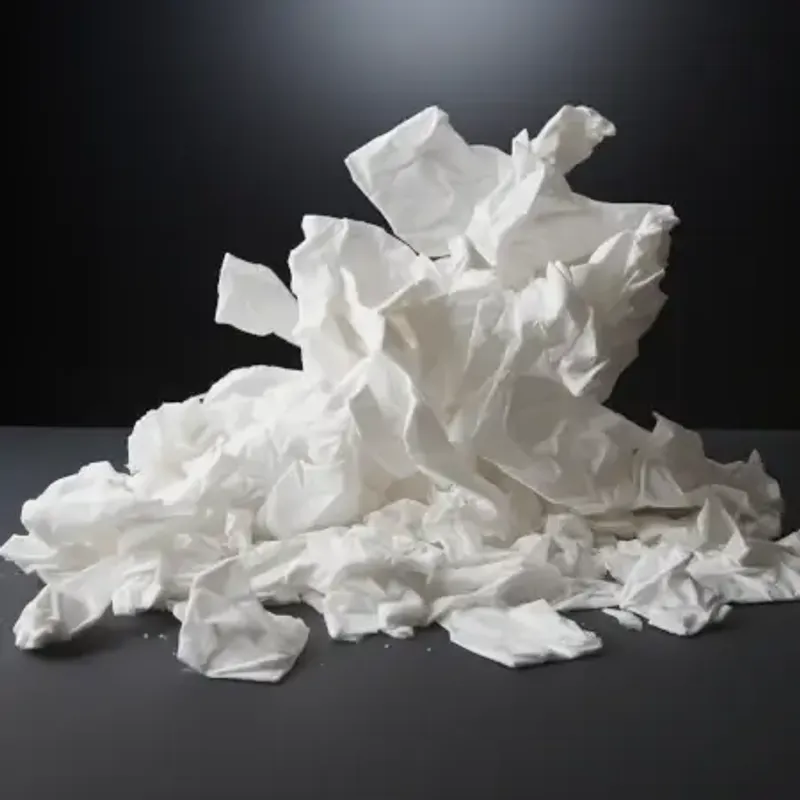

In 2007, "flushable" wipes came on the market. As the wipes increased in popularity and sales increased, the problem at the pumps increased as well. Unlike toilet paper, wet wipes fail to disintegrate. These wipes are not breaking up in the sewer systems the way ordinary toilet paper does. After the wipes are flushed, they tend to bind and clump together, creating huge balls which get tangled in the pumping equipment.

Challenges and Solutions

Sewerage authorities and wastewater treatment facilities continue to be challenged by the increasing volume of sanitary wipes. These wipes cause time-consuming bottlenecks, clogging the pumps, causing them to break down and redirect stagnant wastewater back toward houses. The severity of this problem has led to nationwide media attention.

Some municipalities report accumulating anywhere between $400,000 up to $18 million in related to costs to the district. The TASKMASTER® TM8500 grinder solves this major problem for countless municipalities, lowering downtime and costs.

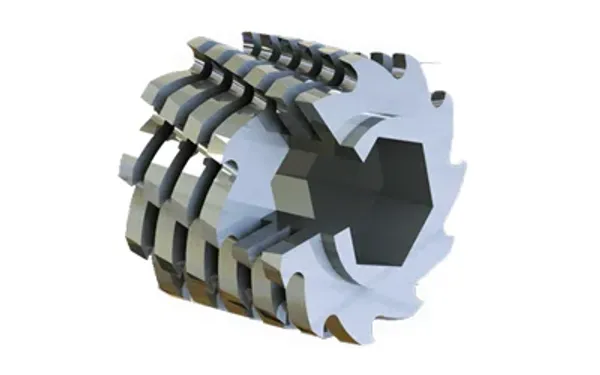

The TASKMASTER® TM8500 grinder has the advantage of CUTTER CARTRIDGE® technology for superior performance. The CUTTER CARTRIDGE combines 6 cutters and 6 spacers into rugged one-piece elements, greatly reducing individual cutter parts and increasing unit strength and reliability.

As a specialist in the size reduction and wastewater industry for over 50 years, we can offer you a custom solution. Our grinders are designed with treatment works in mind and can handle most of the difficult waste including "flushable" wipes.

Need Help With Your Wipes Application?

Our engineers have decades of experience solving wipes challenges. Tell us about your process and we'll recommend the best fit.

See It in Action

Taskmaster Wipes Grinder

Municipalities have deployed heavy-duty wastewater grinding and screening equipment at strategic locations in their waste system to prevent wipes accumulations. With TASKMASTER grinders in place, they can greatly reduce or eliminate the plugging and accumulation of wipes.

Industries & Applications

Explore Other Industries

Trusted by Industry Leaders Worldwide

Engineering Excellence Since 1918

Let's Find the Right Solution for Wipes

Our team is ready to help you select the right equipment for your wipes application and operating conditions.