For the past eight years, a paper products manufacturer has used the DELUMPER® 1075LP Lump Breaker in an unusual application on an expensive process line. The material being processed is a mix of carbon and sulfuric acid. During production, tramp materials such as ferrous and nonferrous bolts become trapped in the products and can play havoc on the downstream equipment if they are not removed. According to the plant manager: “We tried all kinds of metal separators and none of them did what we wanted. They couldn’t handle non-ferrous objects or they didn’t work on metal bolts trapped in the product. We use the DELUMPER LP like a sacrificial component to catch both kinds of material and it has been the best solution for our needs.”

During the processing operation, over-sized lumps and clumps are de-agglomerated by the DELUMPER’s long fingers to a size that easily fits through the unit’s heavy bar grating. Encapsulated bolts are broken free from the product and are caught on the grating. The unit is installed in a free falling position.

“We want to purchase another 1075 LP Crusher with a finer grating to capture even smaller bolts,” concluded the plant manager. “It definitely protects our equipment.”

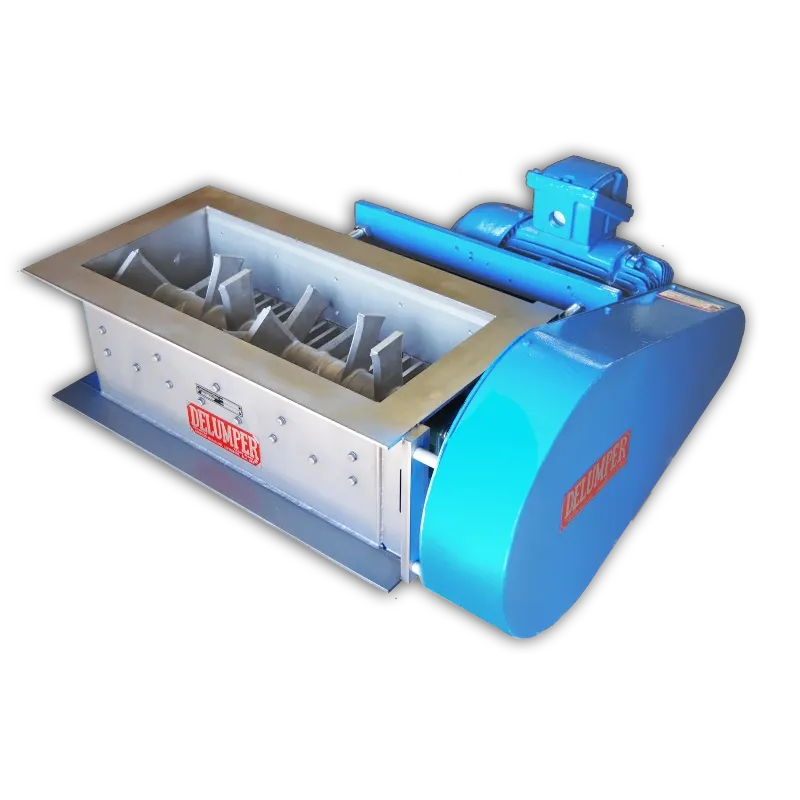

The DELUMPER 1075 LP Crusher is provided with a one-piece seamless uni-body housing. The extended LP cutter teeth rotate completely through a heavy bar cage, self-clearing the slots with each rotation. Each tooth is built for precise balance, interchangeability and smooth operation. Optional features include an extended outboard bearing, convenient side door for easy access and a hopper for feeding. Output sizes are adjustable by changing the speed or the comb. The size of the material handled could be as large as the throat opening. The ultra compact DELUMPER Crusher is designed to be used in open or closed systems such as ducts, chutes or pipes. The unit requires only 13″ headroom space inline.

The DELUMPER Lump Breaker can be supplied as a stand-alone unit crusher or as part of a complete engineered system.