A pharmaceutical manufacturer was faced with major waste management concerns. They urgently needed a powerful shredding system capable of quickly and efficiently reducing bulky pharmaceutical rejects, packaging and literature to an unrecognizable condition. The company had recently purchased shredding equipment to replace older units, which were failing, but soon encountered unexpected problems. Pharmaceutical material passing through the carbon steel shredders often contained corrosive chemicals, which eventually eroded the units.

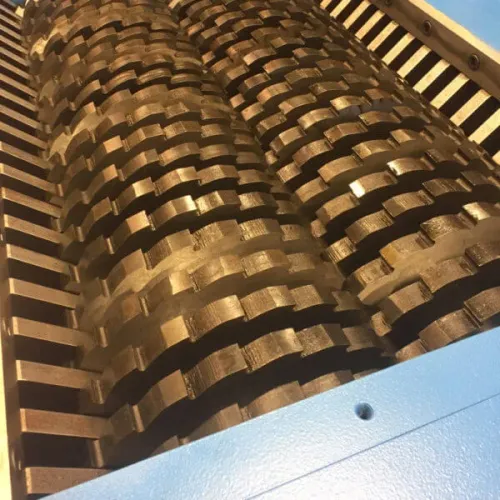

A better solution was required and the manufacturer called on Franklin Miller for help. FMI engineers met on site with the plant manager, evaluated the situation and designed a multi -stage shredding system employing two reduction stages. For the primary stage, a powerful twin shaft TASKMASTER® TM2300 industrial shredder was used to quickly reduce copious amounts of large, bulky material. The output was then sent to a VULCANATOR® KM20 granulator for second stage, ultra fine shredding.

In designing the system, very specific conditions had to be met. The shredders were constructed of corrosion-proof stainless steel, easy to clean and dust tight. The TASKMASTER industrial shredder featured a split body frame that allowed removal of each cutter assembly as one piece to simplify maintenance. The units were provided complete with common support stand, input and intermediate hoppers and completely integrated control system with an overload sensing controller.

According to the plant manager, the TASKMASTER Multi-Stage Shredding System worked exceptionally well from the day it was installed. It was so successful that another pharmaceutical manufacturer, after a visit to inspect the system, purchased a similar one. “We’re very satisfied that we made the right decision,” he concluded.

TASKMASTER Multi-Stage Shredding Systems offer powerful shredding capabilities and provide the most secure destruction for high volume applications. An innovative tandem arrangement incorporates a primary and secondary shredder or grinder, which can be configured to handle many special requirements. The units easily reduce very large or very tough solids en masse including bulk bags, medical waste, bottles and containers, packaging, cardboard, hazardous wastes, plastics, documents and labels and much more.