The Southern Research Institute in Birmingham, Alabama conducts basic research for medical, environmental and engineering companies. The institute was faced with major waste management and disposal problems. The laboratories in the facility produce copious amounts of waste, much of it made of plastic and medical packaging materials. In order to be incorporated into landfills, it was necessary to reduce the waste to an unrecognizable state. The facilities manager considered incinerating the materials but realized that was not a viable disposal method.

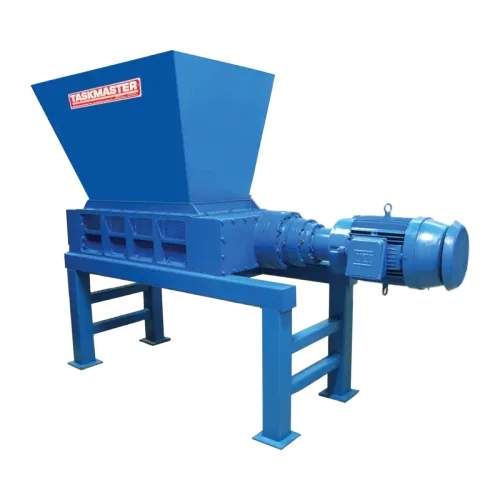

Clearly, a better alternative was desperately needed. After reviewing a video featuring Franklin Miller TASMASTER® industrial shredders, Facilities Manager, Thomas Hurn, found what he was looking for. ” I saw at once that it had the capacity requirements to manage the waste generated,” he said. “And based on what I saw, it was the best buy for the money.”

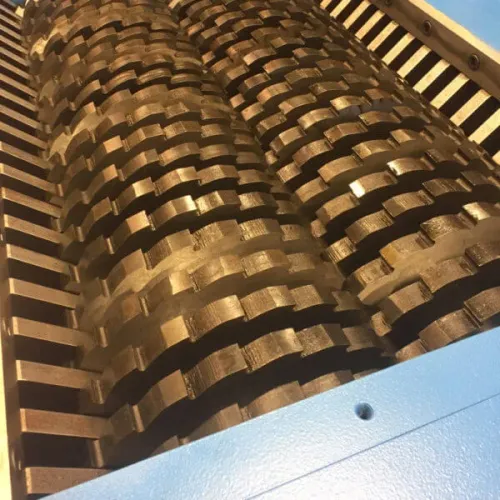

TASMASTER TM2300 shredders are versatile units with remarkable shredding capabilities on a wide variety of materials. Using counter-rotating banks of intermeshing cutters, they efficiently reduce bulk solids up to 80%. The units cut storage and disposal costs while aiding in the safe disposal of wastes. These units can reduce landfill costs, aid in recycling off-spec materials and waste, and enhance processing.

Since installation, the TASMASTER TM2300 industrial shredder has worked exceptionally well. According to Mr. Hurn, “We’ve had no problems. It’s a well-built piece of equipment as far as ruggedness and heavy construction. We’re very satisfied that we made the right decision.”