Introduction

As the world's population continues to grow, so does the need for effective wastewater treatment. Properly managing wastewater is essential to maintaining the health and safety of our communities and the environment. A critical component of wastewater treatment is the protection of the pumps used in these systems. In this blog post, we'll explore the importance of grinding in wastewater treatment pump protection and why it's crucial to the overall efficiency and success of these systems.

The Role of Pumps in Wastewater Treatment

Wastewater treatment plants rely on a variety of pumps to move water and waste through the treatment process. These pumps are responsible for tasks such as transferring raw sewage, pumping treated effluent, and recirculating sludge. The pumps must be able to handle solid materials, including debris and waste, which can be found in wastewater.

The Challenge: Protecting Pumps from Damage

One of the most significant challenges faced in wastewater treatment is the potential damage to pumps caused by solid materials, such as rags, plastics, and other debris. If these materials are not adequately managed, they can clog or damage the pumps, leading to costly repairs, downtime, and decreased efficiency in the treatment process.

The Solution: Grinding in Wastewater Treatment

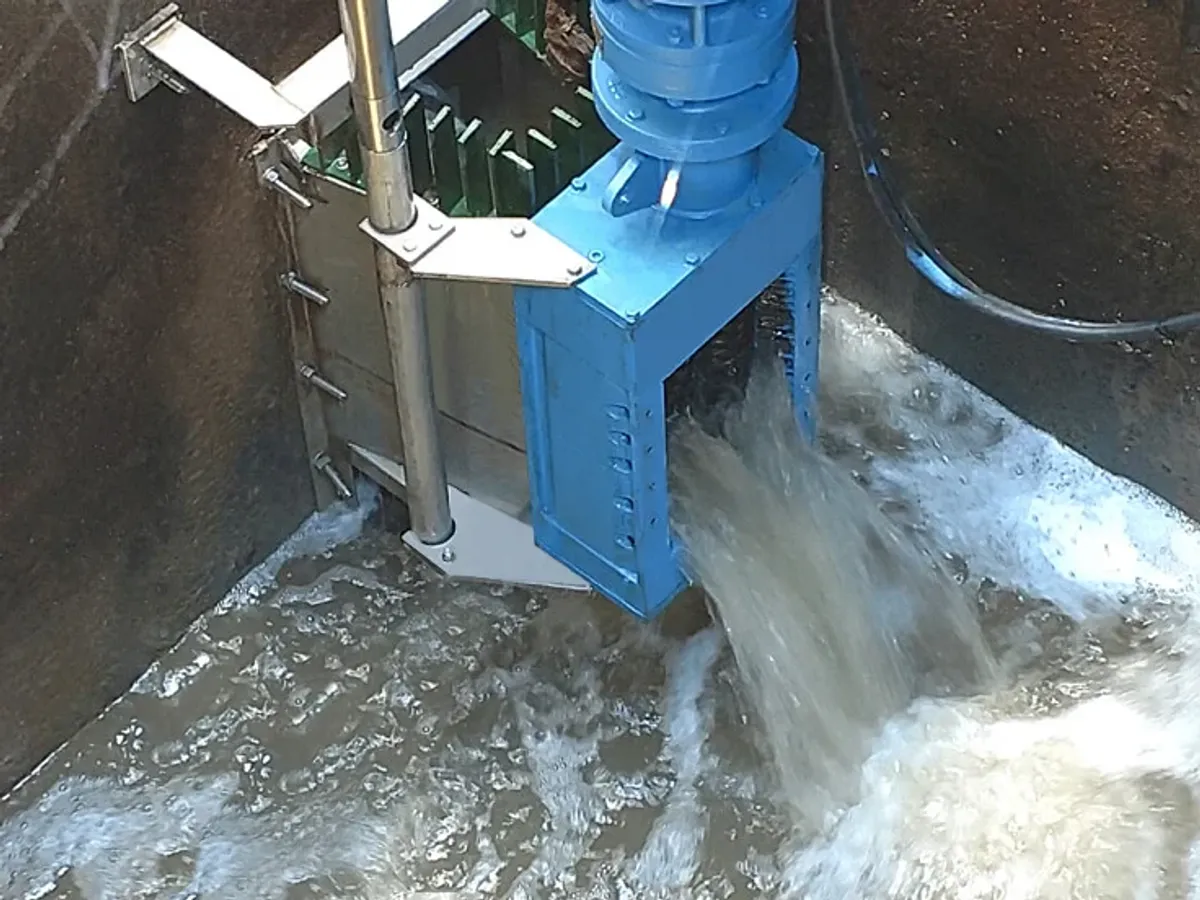

Grinding plays a critical role in protecting wastewater treatment pumps from damage. By breaking down solid materials into smaller particles, grinding equipment helps prevent clogs and damage to pumps, ensuring they continue to operate efficiently.

Inline grinders, such as those manufactured by Franklin Miller, are installed directly in the wastewater flow path. These grinders use sharp, hardened steel cutters to shred and reduce the size of debris, making it easier for the pumps to handle and transport the materials.

Benefits of Grinding for Wastewater Pump Protection

- Increased Pump Efficiency: With solid materials effectively ground into smaller particles, pumps can operate more efficiently and with less strain. This reduces the likelihood of clogs and damage, ensuring the wastewater treatment process runs smoothly.

- Reduced Maintenance Costs: Grinding helps prevent clogs and pump damage, which in turn leads to less frequent maintenance and repair costs. This not only saves time but also reduces the overall expense of wastewater treatment plant operation.

- Prolonged Pump Lifespan: By protecting pumps from damage and reducing strain, grinding equipment helps extend the life of wastewater treatment pumps. This results in long-term cost savings and increased operational efficiency.

- Environmental Impact: Properly functioning pumps are essential for effective wastewater treatment. Grinding equipment ensures that pumps can effectively manage solid materials, leading to more successful treatment outcomes and a reduced impact on the environment.

Franklin Millers Offerings

The Taskmaster is a powerful grinder that is ideal for a variety of applications, including solids reduction, wastewater treatment, and more. It is available in several different models, each with its own unique features and capabilities. Some of the key benefits of the Taskmaster include its ability to handle tough materials, its low maintenance requirements, and its high capacity grinding capabilities.

The Dimminutor is a versatile grinder that is designed to handle a wide range of solids, including wipes, rags, and other tough materials. It is ideal for use in wastewater treatment facilities and other high flow environments where solids reduction is a critical component of the process. The Dimminutor is available in several different sizes and configurations to meet the specific needs of each application.

The Super Shredder is a high-performance inline grinder that is designed to handle large volumes of solids and sludge. It is ideal for use in wastewater treatment facilities, food processing plants, and other industrial settings where solids reduction is a critical component of the process. Some of the key features of the Super Shredder include its ability to handle tough materials, its low maintenance requirements, and its high capacity shredding capabilities.

Conclusion

Grinding is a crucial component in wastewater treatment pump protection, ensuring that these essential systems continue to operate efficiently and effectively. By incorporating grinding equipment into the wastewater treatment process, operators can reduce maintenance costs, extend pump lifespans, and ultimately contribute to a healthier environment. As the demand for wastewater treatment continues to grow, the importance of grinding in pump protection will only become more critical to the success of these systems.