Interested In Learning More About Our Cardboard Shredders?

Industrial Cardboard Shredders

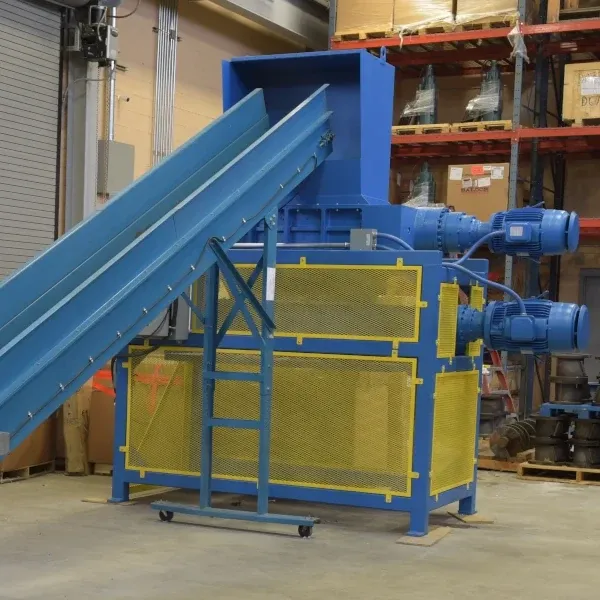

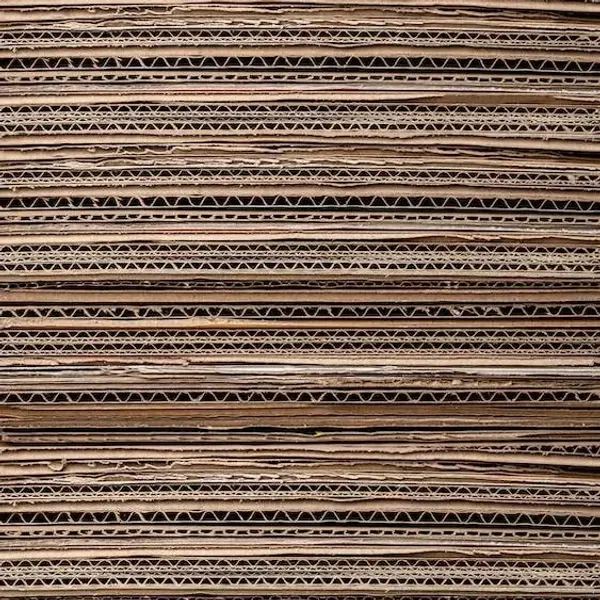

At Franklin Miller, we understand the crucial role of efficient waste management in today's business landscape. Our state-of-the-art cardboard shredders are not just machines; they're your partners in sustainable waste management. Designed to meet the diverse needs of various industries, our shredders transform bulky cardboard waste into manageable, recyclable pieces, contributing to your company's environmental goals.

4

Products

Since 1918

Established

Made in USA

Manufacturing

Livingston, NJ

Headquarters

Cardboard Products

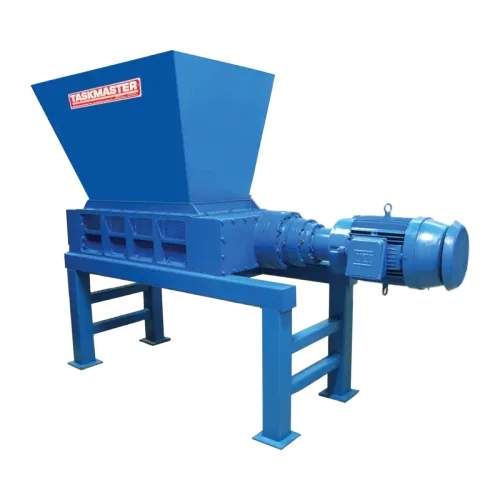

TASKMASTER® TM1600 Shredder

Interested In Learning More About Our Taskmaster® TM1600 Shredder?

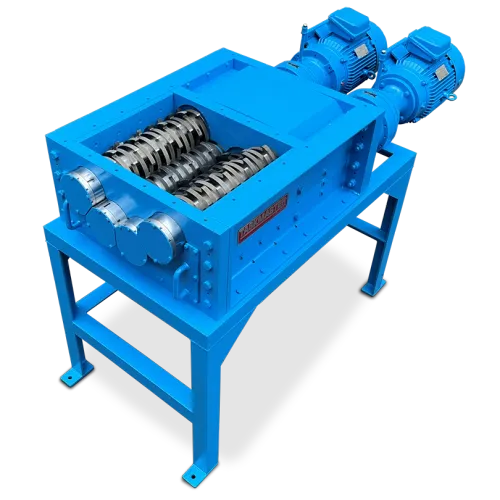

TASKMASTER® TM2300

Interested In Learning More About Our Taskmaster® TM2300?

TASKMASTER® QS2400

Interested In Learning More About our Taskmaster QS2400?

TASKMASTER® QS3200

Interested In Learning More About our TASKMASTER® QS3200?

Superior Shredding Performance

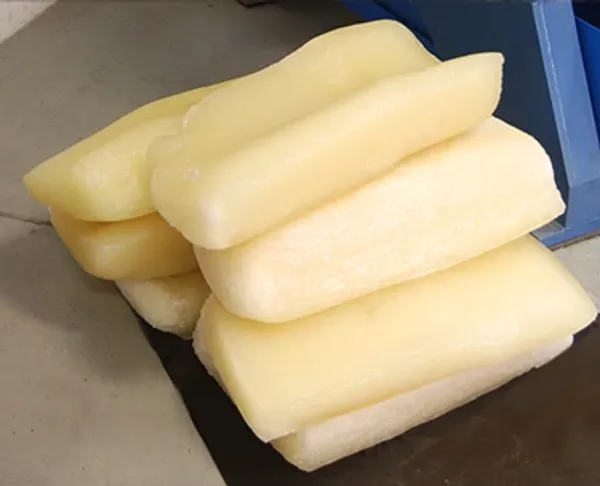

Power and Precision: Engineered for high-volume processing, our shredders boast powerful motors and precision cutting technology. This ensures consistent shredding, handling everything from thin sheets to multi-layered cardboard with ease.

Durability and Reliability: Constructed with high-grade materials, our shredders are built to last. They require minimal maintenance, offering uninterrupted operation and longevity.

Customizable Solutions: Recognizing diverse industry needs, we offer customizable shredder models. Tailor the shredding size, power, and capacity to fit your specific requirements.

Model for Every Need

Our TASKMASTER series offers a range of models to suit various business sizes and needs:

TASKMASTER TM8500: Small-Scale Efficiency

- Ideal for small businesses or compact spaces.

- Compact design with efficient shredding capability.

- Perfect for handling moderate volumes of cardboard waste.

TASKMASTER TM1600: Medium-Scale Power

- A step up for medium-sized operations.

- Increased capacity and power for larger cardboard volumes.

- Balances size with performance for growing businesses.

TASKMASTER TM2300: Industrial-Scale Robustness

- Our most powerful model for large-scale needs.

- Handles high volumes of cardboard with advanced shredding technology.

- Durable and reliable for continuous, heavy-duty operation.

Applications

Franklin Miller's cardboard shredders are essential in a wide range of industries for efficient waste management:

- Retail and Supermarkets: Manage packaging waste efficiently.

- Warehousing and Distribution: Streamline waste from shipped products.

- Manufacturing: Keep production areas clean by recycling packaging materials.

- Offices and Educational Institutions: Easily handle cardboard waste from supplies.

- Event Management and Public Venues: Manage large volumes of waste at events.

Our shredders offer practical, eco-friendly solutions for handling cardboard waste in various settings, enhancing operational efficiency and sustainability.

Need Help With Your Cardboard Application?

Our engineers have decades of experience solving cardboard challenges. Tell us about your process and we'll recommend the best fit.

Industries & Applications

Explore Other Industries

Trusted by Industry Leaders Worldwide

Engineering Excellence Since 1918

Let's Find the Right Solution for Cardboard

Our team is ready to help you select the right equipment for your cardboard application and operating conditions.