American Laboratories, Inc. is a leading manufacturer of enzyme products for many food, dietary supplements, nutritional and industrial applications. The company has grown steadily, currently operating three facilities in Omaha, Nebraska. To keep pace with this expansion, the company realized, some years ago, that a more efficient way to process the enzyme material was necessary. After examining their options, they made a decision to purchase a Franklin Miller DELUMPER® Crusher DC1077S4.

“We use the DELUMPER Crusher to break up large cakes of enzyme products,” explains Vern Maly, Vice President of Production. “The solid, crunchy material is easily broken up into smaller pieces by the unit so that it can be further milled.”

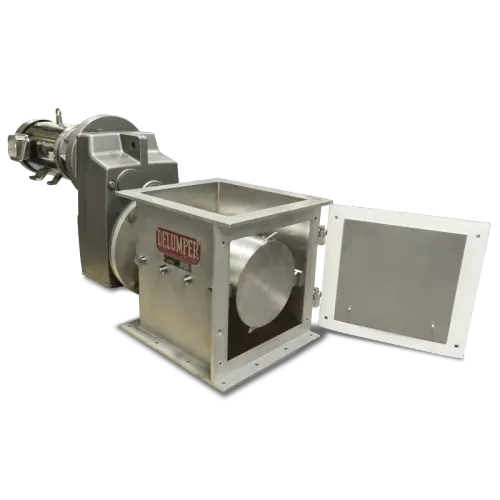

“The DELUMPER Crusher suits our needs. Because it runs at a slower speed, it doesn’t generate much dust. When you are dealing with enzymes, that is very important,” says Maly. “Ease of cleaning is another benefit,” he continues. “We take off the cover, slide out the drum, clean it daily and its ready to go.”

“We’re very satisfied with the DELUMPER Crusher,” concludes Maly. “It worked well immediately after we installed it and, after seven years, the crusher continues to operate trouble-free.”

The DELUMPER® S4 series crushers are specially designed and built to meet the highest quality and sanitary standards. The units employ a precision aligned, smooth rotating drum with integral teeth that rotate through a set of sizing combs. This mechanism produces a once-through, non-destructive crushing action that reduces oversized particles to their basic grain size without over-grind or over-work of material. The result is improved product consistency for enhanced processing, feeding and packaging.

The units feature an ultra-sanitary design, easy interior access, cantilevered design, clean-in-place capability, quick change-over of cutting elements and a meticulously polished finish. A convenient access door provides fast and easy access to the interior of the cutting chamber for cleaning.