PIPELINE DELUMPER®

The PIPELINE DELUMPER® is a proven inline lump breaker that chops, disperses, and suspends solids directly within fully enclosed pipe systems, eliminating blockages without interrupting flow.

Key Features

- Low Friction Cutter Design

- Individually Replaceable Teeth

- Heavy Duty Precision Construction

- High Capacity

- Minimal Fines

Established 1918 · Made in USA · Livingston, NJ

Product Overview

Description

- Cutter Technology

- Low friction cutter design with individually replaceable teeth

- Mounting Options

- Inline installation with standard 150# ASA flanges; optional up to 600# flanges

- Construction Materials

- Carbon steel, 304L or 316L stainless steel, and special nickel alloys

- Features

- Ultra-compact design, self-clearing mechanism, improves mixing and dissolving, protects downstream equipment, optional sizing screen and replaceable liner system

The ultra-compact PIPELINE DELUMPER® is designed for easy installation in straight-thru, liquid, pneumatic or gravity systems. This unit aggressively reduces solids up to the full pipe size with a self-clearing, self-feeding mechanism. It is supplied with an effective seal system housed in an easy to maintain bearing/seal cartridge. This cartridge design eliminates the need for plant personnel to handle delicate seal components. A choice of seals is available.

Options

Customize this product for your application

The PIPELINE DELUMPER® converts a solids-laden stream into a fully suspended homogeneous flow ... instantly. It stops settling out, clustering and over-pressure. The reduced particles are entrained in the stream, away from the pipe walls. Scale that becomes dislodged from reactors, silos and tank is crushed before it can impede the flow.

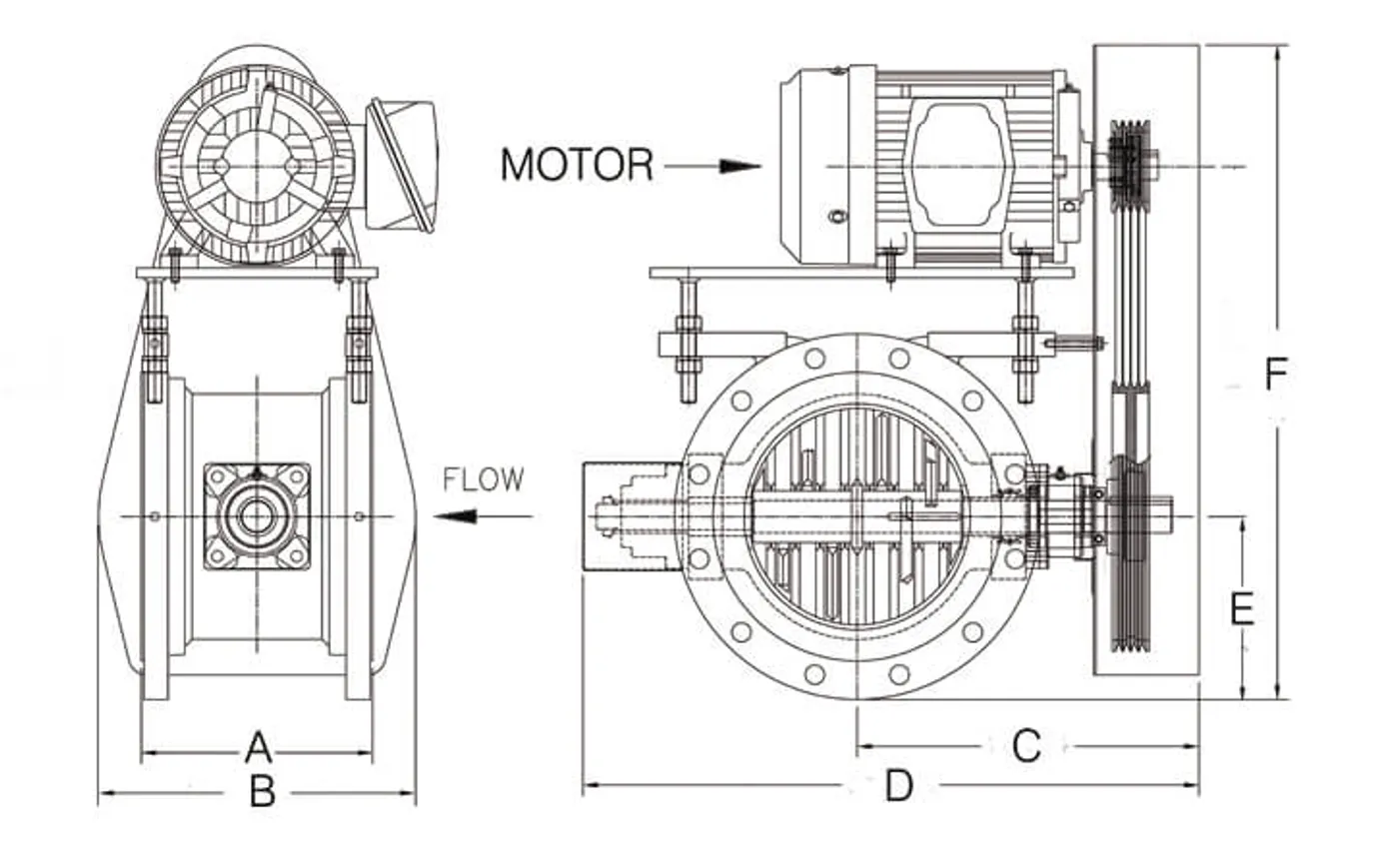

Dimensions

| Model No. | Pipe Size | A | B | C | D | E | F | Typ HP |

|---|---|---|---|---|---|---|---|---|

| PD3 | 3″ | 5.5″(140mm) | 10.2″(259mm) | 9.69″(246mm) | 17″(432mm) | 5.12″(130mm) | 20″(508mm) | 2 |

| PD4 | 4″ | 6″(152mm) | 10.2″(259mm) | 9.875″(251mm) | 18″(457mm) | 5.12″(130mm) | 20.69″(525mm) | 5 |

| PD6 | 6″ | 7″(178mm) | 12″(305mm) | 12.75″(324mm) | 22.75″(578mm) | 6″(152mm) | 23.38″(594mm) | 5 |

| PD8 | 8″ | 8″(203mm) | 16″(406mm) | 15″(381mm) | 25.62″(651mm) | 8″(203mm) | 32″(813mm) | 10 |

| PD10 | 10″ | 10″(254mm) | 16.5″(419mm) | 16″(406mm) | 28.1″(714mm) | 8″(203mm) | 33.81″(859mm) | 10 |

| PD12 | 12″ | 12″(305mm) | 16.5″(419mm) | 17.75″(451mm) | 35″(889mm) | 9.5″(241mm) | 34″(864mm) | 15 |

| PD14 | 14″ | 14″(356mm) | 16.5″(419mm) | 17.75″(451mm) | 36.25″(921mm) | 10.5″(267mm) | 37″(940mm) | 20 |

| PD16 | 16″ | 16″(406mm) | 37″(940mm) | 25.10″(637mm) | 44″(1118mm) | 18.25″(464mm) | 52″(1321mm) | 25 |

| PD18 | 18″ | 18″(457mm) | 37″(940mm) | 26.10″(663mm) | 46″(1168mm) | 18.25″(464mm) | 52″(1321mm) | 30 |

| PD20 | 20″ | 20″(508mm) | 37″(940mm) | 28″(711mm) | 52″(1321mm) | 16″(406mm) | 62″(1575mm) | 40 |

| PD24 | 24″ | 24″(610mm) | 41″(1041mm) | 31″(787mm) | 55″(1397mm) | 19.12″(486mm) | 66.75″(1695mm) | 50 |

| PD30 | 30″ | 30″(762mm) | 55″(1397mm) | 36″(914mm) | 63″(1600mm) | 27.5″(698mm) | 78″(1981mm) | 75 |

| PD36 | 36″ | 36″(913mm) | 74″(1880mm) | 45″(1143mm) | 82.25″(2089mm) | 37″(940mm) | 98.5″(2502mm) | 100 |

Configurations

Customize this product for your application

The PIPELINE DELUMPER® can be configured to meet most application requirements. Units are supplied with standard 150# ASA flanges and can be supplied with up to 600# flanges. Packings, mechanical seals or nitrogen purge deals can be provided.

A unique replaceable liner system allows for the complete periodic renewal of the unit interior. An optional sizing screen can be provided for fine particle reduction. Controls and zero speed indicators are also available. Units are provided in carbon steel, 304L or 316L stainless steel, and special nickel alloys.

A unique hardfacing option is available for extended cutter life under abrasive conditions.

See It in Action

PIPELINE DELUMPER In Action

Technical Specifications

- Cutter Technology

- Low friction cutter design with individually replaceable teeth

- Mounting Options

- Inline installation with standard 150# ASA flanges; optional up to 600# flanges

- Construction Materials

- Carbon steel, 304L or 316L stainless steel, and special nickel alloys

- Features

- Ultra-compact design, self-clearing mechanism, improves mixing and dissolving, protects downstream equipment, optional sizing screen and replaceable liner system

Need Help Choosing the Right Solution?

Our engineers have over a century of experience matching equipment to applications. Tell us about your process and we'll recommend the best fit.

Applications & Usage

Where This Product Is Used

More to Explore

Related Crushers

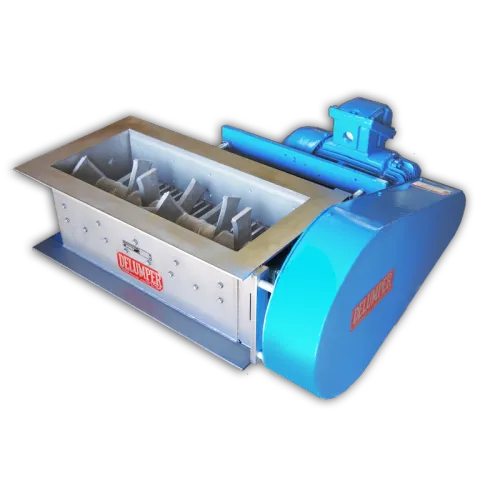

DELUMPER® L

Interested In Learning More About Our Delumper® L?

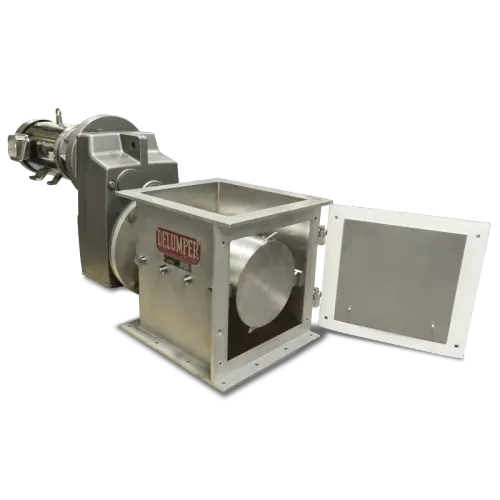

DELUMPER® LP

Interested In Learning More About Our Delumper® LP?

DELUMPER® Multi Shaft LP

Interested In Learning More About Our Delumper® Multi-Shaft LP?

DELUMPER® S4

Interested In Learning More About Our Delumper® S4 Sanitary Crusher?

VULCANATOR® Rubber Granulator

Interested In Learning More About Our Vulcanator® Rubber Granulator?

DELUMPER (BBU) Bulk Bag

Interested In Learning More About Our Delumper® Bulk Bag Unloader?

Trusted by Industry Leaders Worldwide