SCREENMASTER ES

The SCREENMASTER ES externally fed rotary drum screen provides advanced solids removal for municipal and industrial wastewater treatment, offering reliable, low-maintenance screening performance at high flow rates.

Key Features

- Externally Fed Drum Design

- Low-Maintenance Screening

- High Flow Rate Performance

- Municipal & Industrial Use

Established 1918 · Made in USA · Livingston, NJ

Product Overview

Product Overview

- Construction Material

- Durable stainless steel structure ensures long-term durability and corrosion resistance.

- Self-Cleaning Mechanism

- Automatic internal spray cleaning system prevents clogging and maintains continuous operation.

- Design

- Compact, enclosed design minimizes odor and reduces maintenance needs.

- Screening Process

- Influent flows evenly across the rotating drum surface, capturing solids on the exterior screen while filtered water passes through.

The Screenmaster ES is an externally fed rotary drum screen designed to provide efficient and reliable solids separation in a wide range of wastewater treatment applications. Ideal for municipal headworks, industrial process water, and sludge screening, the unit delivers high-performance screening with minimal operator attention. Its rugged stainless steel construction and enclosed, self-cleaning design ensure long-term durability and cleanliness, even in demanding environments.

As wastewater flows over the drum’s exterior surface, solids are retained while liquid passes through the screen openings. The rotating drum is continuously cleaned by an internal spray system, maintaining open screening surfaces and maximizing throughput. The captured solids are conveyed to discharge, leaving screened effluent ready for downstream treatment. With a compact footprint, customizable screen sizes, and low maintenance requirements, the Screenmaster ES offers a simple yet effective solution for enhancing plant efficiency and protecting downstream equipment.

Screening Process

The Screenmaster ES utilizes gravity to evenly distribute influent flow across the externally fed rotating drum, effectively managing variations in solids concentration. This controlled distribution enhances solids separation and reduces the risk of overload, maintaining reliable performance even with changing wastewater conditions.

Drum rotation, combined with a precision spray cleaning system, eliminates buildup and maintains optimal screening efficiency without manual cleaning. This external-feed design simplifies maintenance by ensuring solids remain on the drum's outer surface, protecting internal components from debris and wear. The screened effluent moves swiftly downstream, minimizing headloss and enhancing overall system efficiency.

Technical Specifications

- Construction Material

- Durable stainless steel structure ensures long-term durability and corrosion resistance.

- Self-Cleaning Mechanism

- Automatic internal spray cleaning system prevents clogging and maintains continuous operation.

- Design

- Compact, enclosed design minimizes odor and reduces maintenance needs.

- Screening Process

- Influent flows evenly across the rotating drum surface, capturing solids on the exterior screen while filtered water passes through.

Need Help Choosing the Right Solution?

Our engineers have over a century of experience matching equipment to applications. Tell us about your process and we'll recommend the best fit.

More to Explore

Related Wastewater Screens

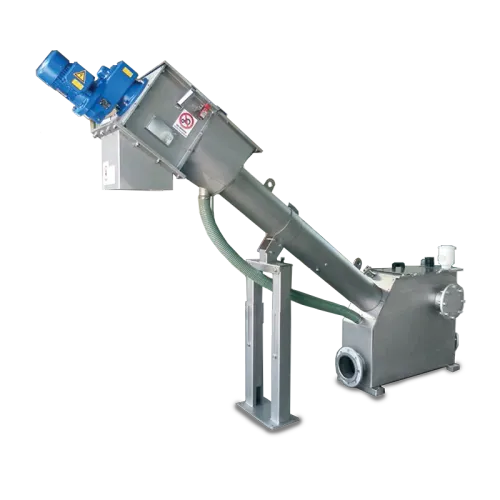

SPIRALIFT® SL

Interested In Learning More About Our Spiralift® SL?

SPIRALIFT® SLV

Interested In Learning More About Our Spiralift® SLV?

SPIRALIFT SI

Interested In Learning More About Our Spiralift® SI?

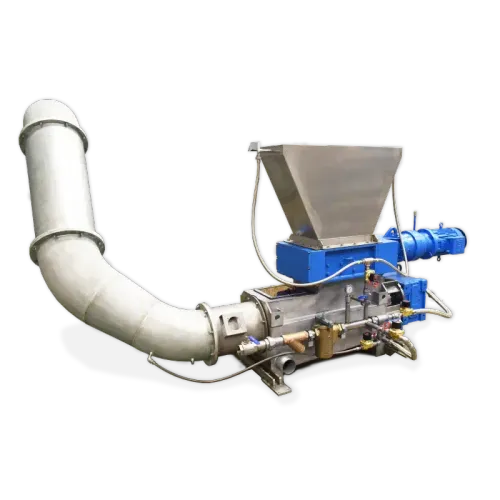

SPIRALIFT® SC Washer / Compactor

Interested In Learning More About Our Spiralift SC®?

SPIRALIFT® SR

Interested In Learning More About Our Screenmaster® SR Septage Receiving Station?

SCREENMASTER® CS Bar Screen

Interested In Learning More About Our Screenmaster® CS Bar Screen?

Trusted by Industry Leaders Worldwide