“The City of Brewer is 10,000 people and treats on average approximately 1.5 – 2 million gallons a day," says Lou Colburn, Chief Operator of the Water Pollution Control Facility in Brewer, Maine.

The Brewer Water Pollution Control Facility is a Grade V facility which uses the Activated Sludge method of treatment to remove conventional and nonconventional contaminants from wastewater across their main water pollution control facility, as well as in 14 pump stations.

Lou Colburn has been the Chief Operator since 1998 and has been at the facility for 47 years. When it comes to dealing with problems at the pumps, he has seen it all.

“We were having problems pumping our activated sludge to our wasting unit and we were having a lot of difficulty with the ball checks. Materials would get caught up in it and we would have to, on average, probably 5 or 6 times every day, dismantle the pump because of debris. A lot of the debris was plastic, other items, tampon applicators. They were creating a lot of issues. We had tried a competitor, for another application, and we were very dissatisfied with the way it was working.”

Lou prides himself on his thorough research, which led him to choose a Franklin Miller TASKMASTER® TM8512 Inline Grinder.

“I did the research, and they seemed to fit the mold of what we were looking for, reliability, dependability, everything. We thought they looked like a good unit. Everything that I read seemed to fit into what we were looking for. So, we purchased it, and it worked out great!”

That grinder was installed in 2006.

“Then in 2016, we built a septic receiving facility, as part of our plant, and of course, septage waste has everything in it, so, we were finding that we were cleaning our primary pumps at least a half a dozen times a week, minimal, and we decided to install a grinder in that line and I think since then, (that’s been on line 4 or 5 years now), and since that time with that particular installation, we have had to clean our pumps once. So, they work very well in our facility, and I am very pleased with the results. They were very well worth the investment.”

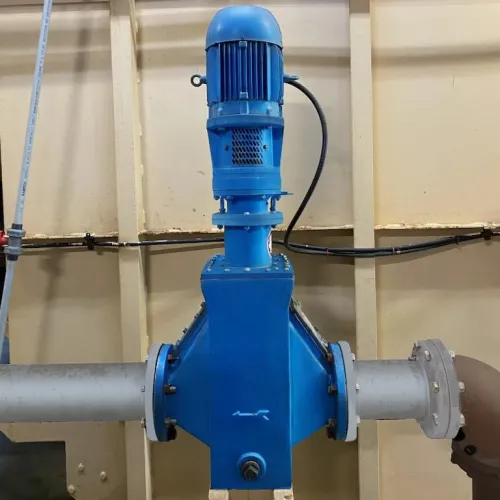

In 2020, a third TASKMASTER® TM8512 was purchased. The installation process was seamless.

“We worked with a company who did a lot of repairs for us, and we had them do the installation and they said they had no issues whatsoever installing that particular piece of equipment. It fit right into the feedline.”

Lou believes that the Cutter Cartridge Technology of the TASKMASTER® grinders has been a great advantage over the competitors. Lou remembers all of the struggles he and his team had before he transitioned to the TASKMASTER® inline grinders. “We had to remove each blade and replace them individually. This is pretty much a godsend. You take the whole thing out just drop the new one back in and you are good to go! It’s pretty incredible.”

“This is great equipment, believe me. I would highly recommend it to anyone. If we have another application for it, we definitely would purchase another.”

Franklin Miller is committed to customer service and offers spare parts readily when needed. However, the Franklin Miller inline grinders at Brewer have never needed spare parts, nor maintenance!