The Brewer Water Pollution Control Facility is a Grade V facility which uses the Conventional Activated Sludge method of treatment to remove conventional and nonconventional contaminants from wastewater across their main water pollution control facility, as well as in 14 pump stations.

They were running a variety of grinders in the plant and found that they were not always working efficiently. In fact, they were having tons of problems with debris such as plastic, wood, and tampons constantly getting stuck in the cutters.

“We had so many problems with those machines,” said Lou Colburn, Chief Operator at Brewer Maine plant.

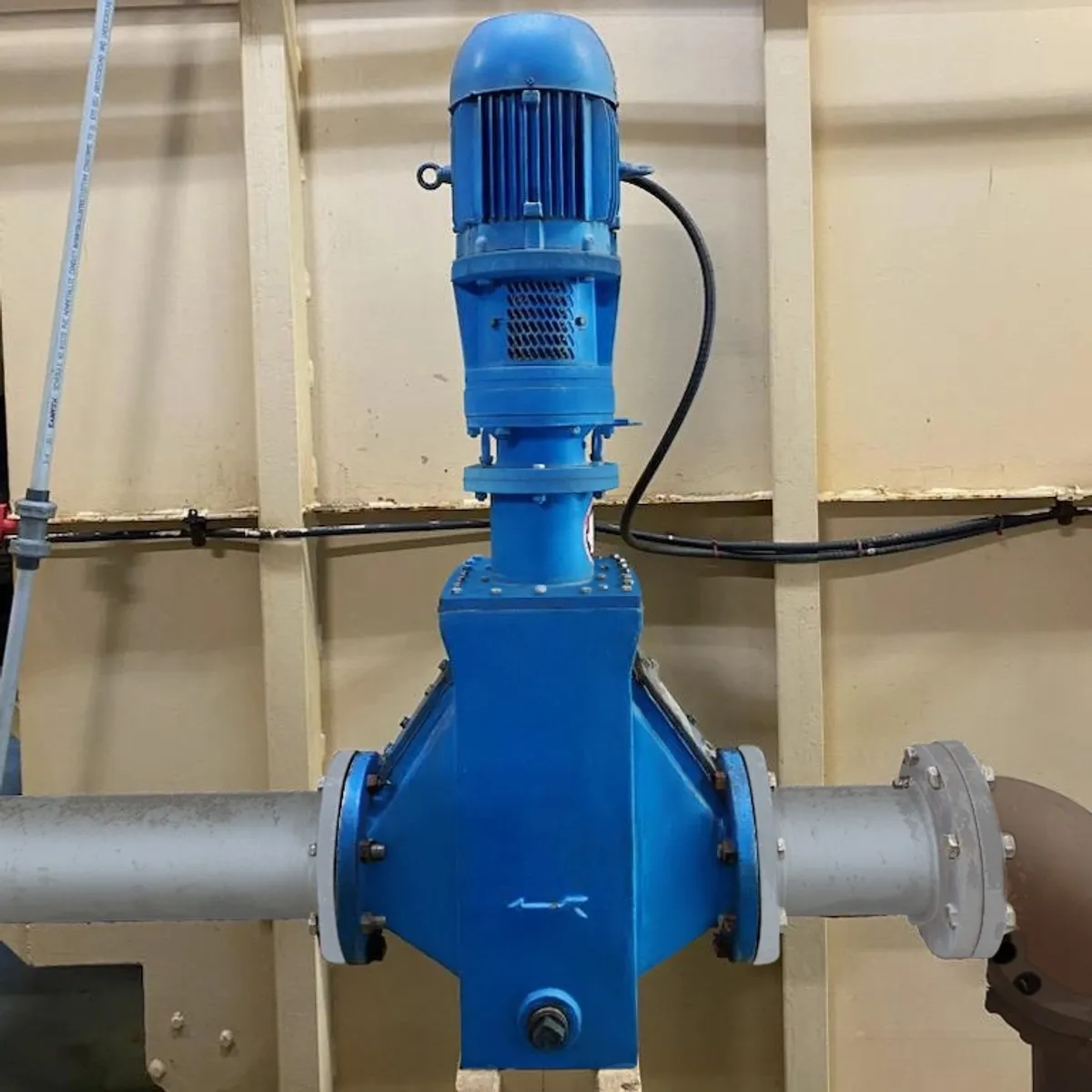

At that point, the plant knew they needed a better solution. Their industry research led them to Franklin Miller’s broad line of municipal grinders. The plant decided to purchase an inline Taskmaster TM8500.

“We bought that first machine about 15 years ago,” Colburn said. “It’s been working great ever since.”

About five years after their first Franklin Miller unit, the plant purchased a second machine to be used for primary sludge. “That machine has been a lifesaver. It’s done everything we need it to do,” Colburn said.

The plant has a dissolved air flotation unit and they also put in a septage receiving station. As their operation grew, so did their problems. Back at their main facility, wipes were constantly clogging up their system. Since they had already had so much luck with their Franklin Miller grinders, they decided to install another inline Taskmaster TM8500.

“We were cleaning pumps on a daily basis,” said Colburn. “We put in another FMI grinder two years ago and it’s fantastic. We have not had to clear it once since the installation. To go from daily clogs to none at all has been incredible.”

The TASKMASTER® TM8500 twin shaft grinders provide unsurpassed grinding of wastewater solids, and design features that make them truly unique. These units have proven their capability and unique reliability in installations worldwide. TASKMASTER grinders feature dependable mechanical seals in a cartridge design and CUTTER CARTRIDGE® Technology.

These grinders reduce pump ragging and problems with downstream equipment by finely reducing such solids as rags, plastics, wipes, paper, disposables, fabrics, wood, bottles and much more. They are built for sewage, sludge, septage and screenings applications in either open channel, inline or gravity installations. Each unit is heavily constructed for low vibration and quiet operation.

“The FMI grinders have saved us a lot of man hours. They really are fantastic. I would highly recommend this machine to anyone. The FMI units have truly been a godsend.”