The Metropolitan District in Hartford Connecticut (MDC) processes millions of gallons of wastewater that flow through more than 1300 miles of sewers a day. Along with the main plant in Hartford, the MDC operates three satellite stations, and multiple pump stations.

Like many wastewater treatment plants, the grinders used at MDC process a lot of solid and human waste that mixes with trash and sewer water, releasing a lot of H2S. This hydrogen sulfite is very hard on the machines.

“This is probably the worst and hardest environment you can put a machine in,” said Nick Martel, maintenance mechanic.

Their previous machines were from a competitor’s company and they broke down all the time. “In our environment, machines will need to berebuilt. That is the nature of our circumstances in this plant. But the old machines broke down so often, we were rebuilding them every six months or so.”

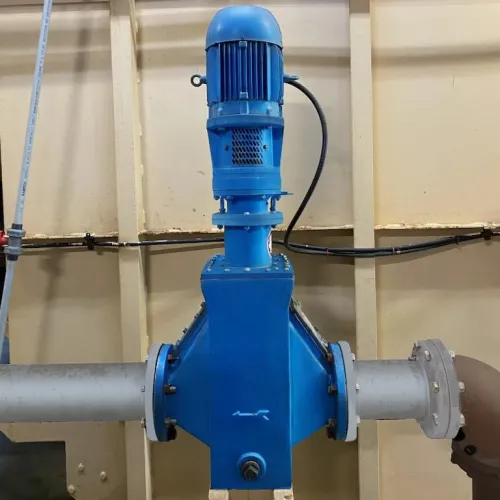

They decided to switch out some of their old machines with Franklin Miller units. To date, the plant has installed at least 30 Franklin Millerunits from the company’s municipal line of products, including Taskmastergrinders, Taskmaster inline grinders, and Dimminutor open channel units.

“The Franklin Miller units are great,” Martel said. “What adifference. In the past we had to rehab machines every six months, eight atmost. Now, with Franklin Miller, we get at least two years.”

The TASKMASTER® TM8500 twin shaft and inline grinders cut through wastewater solids with design features that make them unique. TASKMASTER grinders feature dependable mechanical seals in a cartridge design and CUTTER CARTRIDGE® technology, with two stacks of intermeshing cutters that aggressively pull the solids in and finely reduce them. This CUTTER CARTRIDGE technology replaces 6 cutter disks and 6 spacer disks with a one-piece element for far greater strength, fewer components, no stack loosening or stack re-tightening requirement. These grinders can be installed in gravity or pressurized, vertical or horizontal pipe systems, on the suction or positive side of a pump and are built for sewage, sludge, septage and screenings applications in either open channel, inline or gravity installations.

“The lead time and customer service at FMI is fantastic. Every time I call, they pick up, they respond, and I get what I need quickly. “Our old company had the worst customer service. Calls went nowhere, not to mention their machine parts were made in China. Garbage that didn’t last.”

The DIMMINUTOR® provides automatic screening and grinding of liquid-borne solids with a straight-through open-channel design. This unit reduces plastics, wood, vegetable matter, disposables and other oversized items to a fine particulate. The DIMMINUTOR is designed for reliable operation and easy maintenance. For example, with its cantilevered design, the DIMMINUTOR needs no seals or bearings near the gritty channel floor. The unit’s screen is stationary so it never wears against bottom grit. Each cutter is interchangeable and cutters can be removed or adjusted independently. The unit’s seals and bearings are immersed in an oil bath for long life and low maintenance.

“We are so happy with switched to Franklin Miller. The longevity of these machines is so much better, so there is lots less down time and therefore less money wasted.”