The Musconetcong Sewerage Authority, located in northwest New Jersey, manages an impressive daily volume of over 4.3 million gallons of domestic wastewater. However, the facility was grappling with significant challenges due to its outdated grinders, some of which had been in service for approximately 25 years. These old units, sourced from a competitor, were severely underperforming and, in some cases, had stopped working altogether Their frequent clogs led to persistent maintenance issues and considerable downtime, which disrupted plant operations.

The main problem with the outdated grinders was their tendency to cause recurring clogs in the sludge pumps and secondary clarifiers, primarily due to the fibrous nature of rag materials present in the wastewater. James Schilling, the Executive Director of the Musconetcong Sewerage Authority, highlighted the severity of the issue, stating, “We faced constant blockages in sludge management. This caused significant downtime and affected plant operations.”

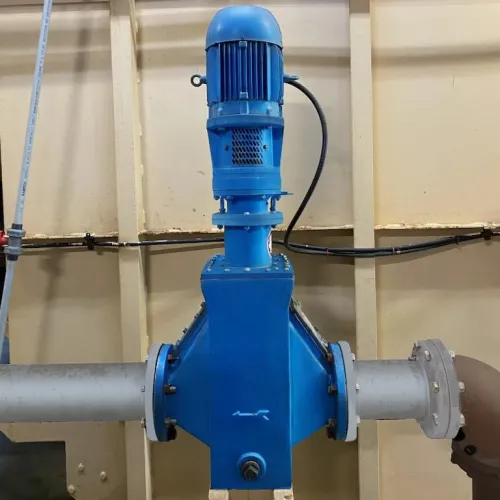

In response to these ongoing issues, the plant decided it was time for an upgrade. After evaluating several options, the authority chose to install Franklin Miller’s Taskmaster® grinders. The decision was influenced by several factors. The streamlined procurement process for the Taskmaster® grinders was a notable benefit, and their promise of simplified maintenance compared to the old units was a key consideration. Additionally, the Taskmaster® grinders featured Cutter Cartridge® technology, which allowed for easy maintenance without the need for adjustments. Their design also fit well within the plant’s existing layout, making them a practical choice.

Schilling expressed his satisfaction with the decision, remarking, “We could have just replaced the old cartridges and kept the housing on the other brand units, but the Taskmaster® offered a better overall solution. It was clear that Franklin Miller’s unit was superior.”

The new grinders were installed in early 2024. Since their implementation, the plant has experienced smoother operations with no further issues of sludge clogs. Schilling observed the improvements, stating, “The Taskmaster® has resolved our clogging issues entirely. The plant is running much more efficiently now.”

The Taskmaster® inline sewage grinders have proven effective in handling various solids, including rags, plastics, and tampons, thanks to their powerful twin-shaft mechanism and Cutter Cartridge® technology. This upgrade has led to a significant reduction in pump downtime and an overall enhancement in plant performance.

James Schilling’s feedback reflects the positive impact of the upgrade: “We’re very pleased with the Taskmaster®. It was definitely the right choice for our plant.” This successful upgrade underscores the benefits of adopting advanced technology to improve operational efficiency and minimize maintenance challenges in wastewater treatment facilities.