The facility, which handles .55 mgd of wastewater from domestic sources as well as from a Veterans home, was getting deluged with rags and other debris spilling over into various areas of the wastewater treatment process causing frequent maintenance headaches. The debris was constantly clogging up the pumps and had to be removed manually. Of particular concern was the solid waste from the Veterans home, which contained enormous quantities of cooking grease. Once the grease entered the waste stream, it congealed into large blocks that coated and clogged the lines, increasing down time and maintenance headaches.

After examining the options with their consulting civil engineer, the facility personnel determined that the best solution would be a screening device to remove the solids. A Franklin Miller SPIRALIFT® Model SL fine screening system was selected for the job.

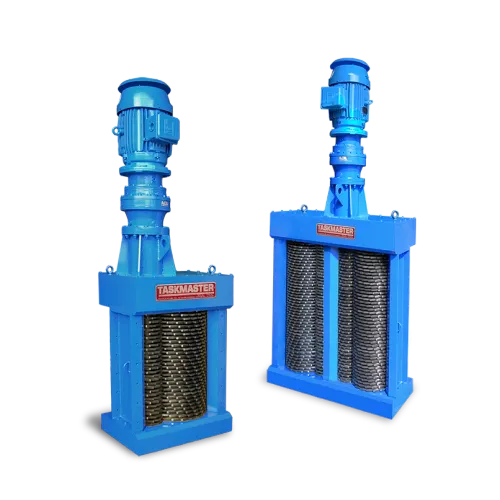

This SPIRALIFT® SL employs a shaftless auger screw and a finely perforated screen that captures debris. The screen is wiped by the auger brushes and conveyed up and out of the system. A TASKMASTER® TITAN® Grinder reduces all the solids assuring a highly dependable system performance.

“We immediately saw the difference,” said Don Moore, wastewater system Supervisor. “The combination of SPIRALIFT and grinder virtually eliminated the debris and most of the grease. In our application, it has helped us immensely.” He concluded.

The SPIRALIFT® is a versatile screening system that is easy to employ for a variety of channel sizes and capacity requirements. The unit features a built-in washing system to clean the debris before lifting them out of the flow. A special control system integrates and coordinates the system’s normal and special functions. The PLC-based control system uses flow level data to cycle the screw to minimize power and wear.

Mr. Moore added, “I am impressed at how the company has always been there when we needed them. Whenever we call them, they get right back to us. I’d definitely recommend the Spiralift System.”