In the realm of industrial shredding equipment, choosing the right shredder can be tough. How do you decide which shredder is best for your application and which will provide maximum operational efficiency and material processing? Two heavy-duty options for shredders are the dual-shaft and the quad-shaft shredders. Not sure which machine you need? Let’s delve into the features, advantages, and applications of both types to help you make uninformed decision to address your specific application and shredding needs.

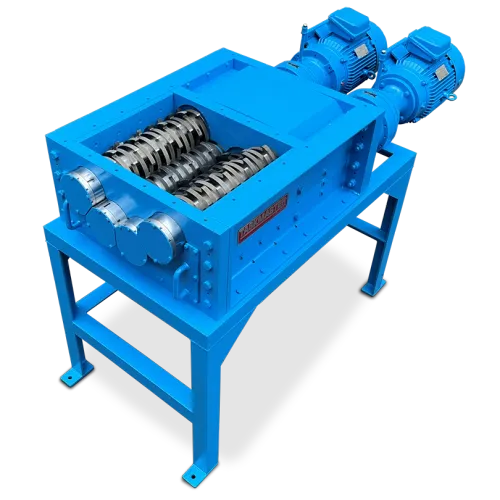

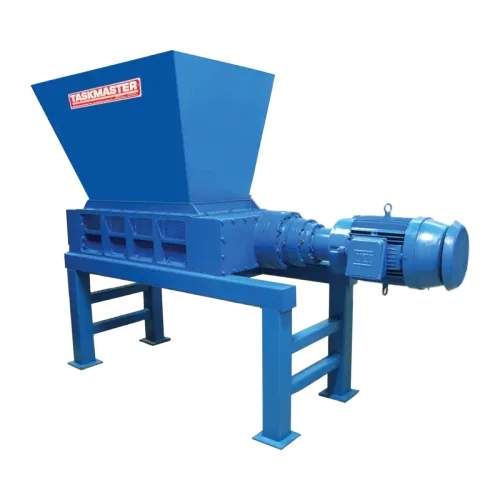

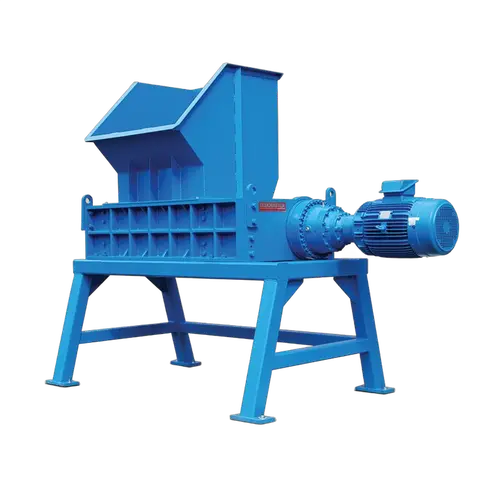

Dual-Shaft Shredders

Dual-shaft shredders, as the name suggests, come equipped with two shafts that rotate in opposite directions. These machines are known for their versatility and are commonly used in various industries, some of which include recycling, electronics, glass, wood, metal, plastic, and larger items like tires.

Top features of dual-shaft shredders:

1. Flexibility and versatility: Dual-shaft shredders can handle a wide range of materials. Their dual-shaft design ensures efficient cutting and tearing of diverse materials.

2. Price and Maintenance: The simple design of dual-shaft shredders results in a lower price. In addition, this simpler unit generally requires less maintenance, which can mean less downtime.

3. Energy efficiency: Because of their lower power requirements, dual-shaft shredders are often more energy-efficient than the quad-shaft shredders, which can result in cost savings over time.

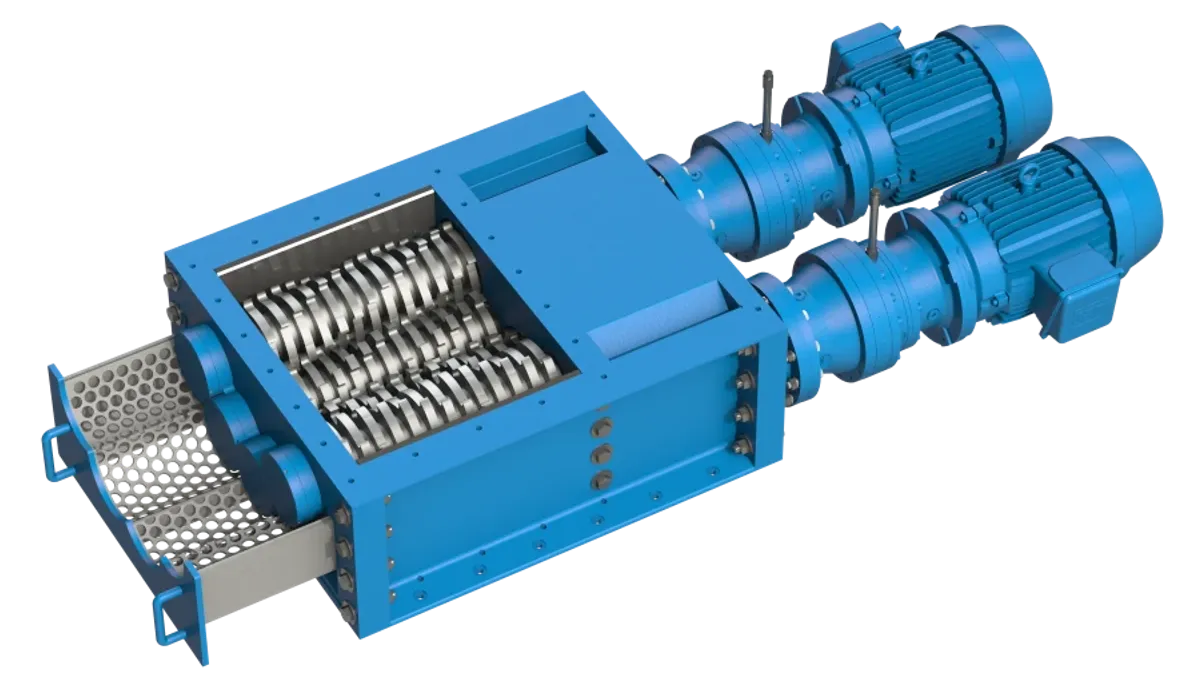

Quad-Shaft Shredders

Quad-shaft shredders have even more powerful shredding action by using four rotating shafts, along with a specially-designed sizing screen. This design increases the shredding capabilities, which can be ideal for applications requiring a higher volume or uniform output of material shredded.

Top features of quad-shaft shredders include:

1. Increased capacity: With two additional shafts, quad-shaft shredders can handle larger volumes of material. This makes them suitable for organizations with high-capacity shredding needs.

2. Sizing screen for homogeneous output: The additional shafts contribute to a more uniform shredding process as the shafts are able to rotate continuously until the material passes through a specially-designed sizing screen until reaching the desired output size. This is particularly useful when dealing with materials that require a precise size output.

3. Heavy-duty applications: Quad-shaft shredders are designed to handle tougher, more challenging materials, including industrial waste and e-scrap.

But, How Do You Choose the Right Shredder for Your Application?

What is your material and what volume are you shredding? Dual-shaft shredders offer flexibility for a wide range of materials at moderate volumes, while quad-shaft shredders are designed for higher volumes and tougher materials.

Do you have any space and/or energy constraints? If you have any concerns about available space and energy, dual-shaft shredders might be the better choice.

What are your output needs? If your operation demands precise output shape or size, a quad-shaft shredder with its specialty sizing screen might be the better option for your application.

There is no one answer when it comes to choosing a shredder. Your specific application requirements will help you choose the type of shredder that will best serve your operation. Specific needs should be taken into consideration, such as the type of the material to be shredded, the volume requirements and precision needs, as well as your available space and energy. Whatever you decide is best, whether the versatile dual-shaft or the powerful quad-shaft, your application will benefit from this crucial piece of your industrial shredding operation.