Interested In Learning More About our Industrial Wastewater Solutions?

Industrial Wastewater

Successful industrial wastewater solutions help reduce customers’ carbon footprint, reclaim water, re-purpose waste for energy, eliminate costly disposal/landfill and protect downstream pumps and equipment.

1

Products

Since 1918

Established

Made in USA

Manufacturing

Livingston, NJ

Headquarters

Industrial Wastewater Products

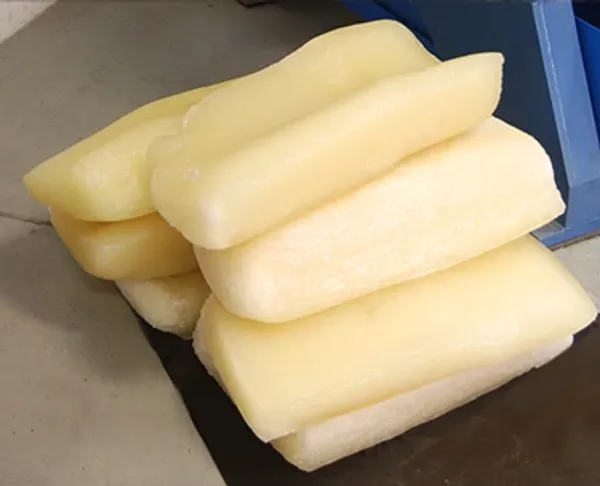

Dairy & Meat Processing

The abundant wastewater from dairy applications is found to be high in solids, oils, phosphorus, and nitrogen. Even cleaning products used to sanitize the plant can often be found in the wastewater. Similarly, meat processing and dairy processing wastewater is often heavily burdened with fats, oils, and grease (FOG) which must be separated and treated. Poultry processing plants have their own challenges. This wastewater has high levels of organic matter, fat and microorganism, which needs to be screened and/or separated.

Industrial Wastewater

Successful industrial wastewater solutions help reduce customers’ carbon footprint, reclaim water, re-purpose waste for energy, eliminate costly disposal/landfill, and protect downstream pumps and equipment. Franklin Miller grinders, screens and packaged solutions have proven their dependability in years of operation worldwide.

Rendering & Slaughterhouse Processing

During the rendering process, waste animal matter is separated from fats and wastewater creating useful animal byproducts and materials to be used for rendering edible and non-edible goods. Slaughterhouse wastewater often includes fatty tissue, hair, feathers, offal, blood, and even parts of the carcass or bones. TASKMASTER® Grinders and the SCREENMASTER® Rotary Drum Screen grind and separate solids, fat and grease, resulting in a clean flow of wastewater.

Seafood Processing

Seafood wastewater, high in TSS and biological oxygen demand (BOD) must be processed and treated. Thawing, eviscerating, washing, pre-cooking, spray cooling, solution filling, can washing and sterilization lead to a lot of wastewater. TASKMASTER® Grinders and the SCREENMASTER® Rotary Drum Screen process and treat the wastewater to meet discharge.

Oil & Gas Processing

Franklin Miller has a multitude of inline processors suitable to handle the complex demands of oil and gas applications.

The unique needs pertaining to the extraction, refining, and transporting of petroleum products can be easily handled by Franklin Miller grinders. For Oil and gas processing, Franklin Miller inline processors such as TASKMASTER® Inline Grinders, DELUMPER® Crushers and SUPER SHREDDER® Inline Processors keep pumps and centrifuges protected by breaking down rocks, cutting stringy plant materials or crushing petrified woods before they can reach or damage downstream equipment.

Need Help With Your Industrial Wastewater Application?

Our engineers have decades of experience solving industrial wastewater challenges. Tell us about your process and we'll recommend the best fit.

Industries & Applications

Explore Other Industries

Trusted by Industry Leaders Worldwide

Engineering Excellence Since 1918

Let's Find the Right Solution for Industrial Wastewater

Our team is ready to help you select the right equipment for your industrial wastewater application and operating conditions.