SCREENMASTER® RT Rotary Drum Screen

Rugged, Internally Fed Rotary Drum Screen for Wastewater & Industrial Screening

The SCREENMASTER® RT is a high-performance rotary drum screen engineered for municipal and industrial wastewater treatment, delivering continuous, efficient solids capture with a compact, self-cleaning design.

Key Features

- Stainless Steel Construction

- Enclosed Odor-Reducing Design

- Internal & External Spray Wash

- High Solids Capacity

- No Internal Chains or Gears

Established 1918 · Made in USA · Livingston, NJ

- RT24050

- RT30070

- RT36070

- RT48096

- RT60120

Product Overview

Description

- Construction Material

- Corrosion-resistant T304 or T316 stainless steel

- Screen Opening Range

- 500 x 500 micron (filter cloth) to 6 mm perforations

- Drum Dimensions

- Up to 60” diameter and 156” (4m) in length

- Cleaning System

- Internal and external high-pressure nozzles; optional brush assembly

The SCREENMASTER® RT rotary drum screen is purpose-built to deliver effective screening for facilities that require continuous solids separation under demanding conditions. Its high-efficiency design helps reduce blockages, lower maintenance costs, and improve plant reliability. The fully enclosed construction enhances hygiene, minimizes odor emissions, and supports operator safety in wastewater facilities, food processors, breweries, and industrial plants.

Customizable screen sizes, screening openings, and mounting options make the RT adaptable to a wide range of installations. It integrates easily into existing systems and offers performance advantages including increased solids capture, extended run time, and minimal operator intervention.

Automated Self-Cleaning System

The SCREENMASTER® RT uses an internal spray wash system to maintain screen cleanliness and optimize performance. Optional external high-pressure spray bars and rotary brush systems are available to further reduce solids buildup and extend operating cycles.

These automatic cleaning features prevent clogging, maintain consistent flow, and reduce the need for manual intervention. With its efficient cleaning action, the RT ensures smooth operation—even in high-solids environments—while helping plants reduce labor and downtime.

Design & Construction

The SCREENMASTER® RT rotary drum screen is built on a heavy-duty stainless steel frame engineered for years of continuous operation in harsh environments. Every wetted component is constructed from corrosion-resistant T304 or T316 stainless steel, ensuring long service life in both municipal wastewater and aggressive industrial applications.

The direct-drive system pairs a C-face motor with an inline gear reducer — eliminating chains, sprockets, and belts that require frequent maintenance. The drum rotates slowly on heavy-duty support rollers rated for a B10 bearing life of 100,000 hours, providing exceptional reliability with minimal wear.

Each rotary drum screen unit includes a PLC-based control system housed in a NEMA 4X stainless steel enclosure, offering full automation of drum rotation, spray wash cycles, and alarm functions. BABA (Build America, Buy America) compliant configurations are available for federally funded infrastructure projects.

Simplified Maintenance and Operation

Routine maintenance on the RT Rotary Drum Screen is quick and straightforward. The unit features tool-free access panels, a compact drive system, and corrosion-resistant components. Without chains, sprockets, or internal gears to maintain, service requirements are significantly reduced.

Its modular construction allows for easy upgrades or part replacements, while the intuitive layout makes it easier for operators to monitor system performance. These features help improve equipment uptime, minimize plant disruptions, and extend service life.

Rotary Drum Screen Applications

The SCREENMASTER® RT is ideal for use in a variety of industries, including:

- Municipal wastewater treatment plants

- Food and beverage production facilities

- Pulp and paper mills

- Textile manufacturing plants

- Industrial process water recovery systems

This rotary drum screen supports operations that require continuous solids separation, effective screening of high solids content, and dependable performance in wet, corrosive environments. Its versatility and capacity make it an essential screening component for both new systems and retrofit applications.

Dimensions

| RT Models | Drum Diameter | Drum Length | Overall Width | Overall Length |

|---|---|---|---|---|

| RT2450 | 24"(610 mm) | 50"(1270 mm) | 44"(1118 mm) | 87"(2210 mm) |

| RT3070 | 30"(762 mm) | 70"(1778 mm) | 50"(1270 mm) | 107"(2718 mm) |

| RT3670 | 36"(914 mm) | 70"(1778 mm) | 56"(1422 mm) | 108"(2743 mm) |

| RT4896 | 48"(1219 mm) | 96"(2438 mm) | 68"(1727 mm) | 135"(3429 mm) |

| RT60120 | 60"(1524 mm) | 120"(3048 mm) | 80"(2032 mm) | 160"(4064 mm) |

See It in Action

Versatility in Municipal and Industrial Applications

Technical Specifications

- Construction Material

- Corrosion-resistant T304 or T316 stainless steel

- Screen Opening Range

- 500 x 500 micron (filter cloth) to 6 mm perforations

- Drum Dimensions

- Up to 60” diameter and 156” (4m) in length

- Cleaning System

- Internal and external high-pressure nozzles; optional brush assembly

Need Help Choosing the Right Solution?

Our engineers have over a century of experience matching equipment to applications. Tell us about your process and we'll recommend the best fit.

Applications & Usage

Where This Product Is Used

Resources

Technical Resources & Downloads

More to Explore

Related Wastewater Screens

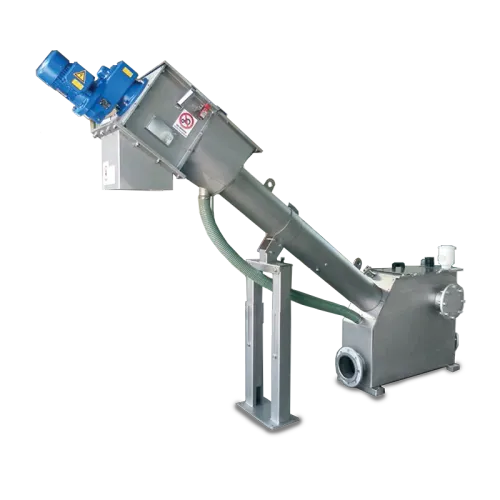

SPIRALIFT® SL

Interested In Learning More About Our Spiralift® SL?

SPIRALIFT® SLV

Interested In Learning More About Our Spiralift® SLV?

SPIRALIFT SI

Interested In Learning More About Our Spiralift® SI?

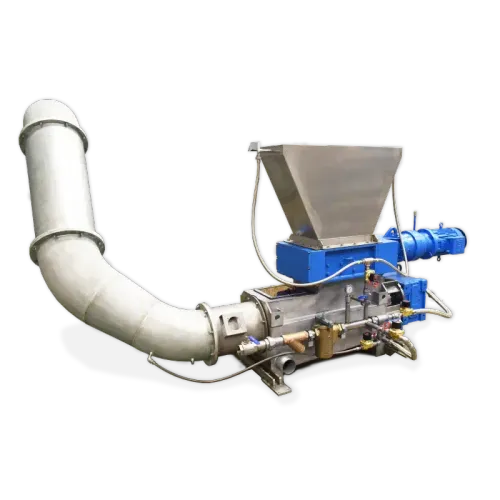

SPIRALIFT® SC Washer / Compactor

Interested In Learning More About Our Spiralift SC®?

SPIRALIFT® SR

Interested In Learning More About Our SPIRALIFT® SR Septage Receiving Station?

SCREENMASTER® CS Bar Screen

Interested In Learning More About Our Screenmaster® CS Bar Screen?

Trusted by Industry Leaders Worldwide

Trusted Since 1918

Ready to Specify the SCREENMASTER® RT Rotary Drum Screen?

The SCREENMASTER RT delivers reliable, efficient fine screening across municipal and industrial applications — built in the USA since 1918.