Interested in Learning More About Our Oil and Gas Equipment?

Oil and Gas Equipment

Franklin Miller has a multitude of inline processors suitable to handle the complex demands of oil and gas applications. The unique needs pertaining to the extraction, refining, and transporting of petroleum products can be easily handled by Franklin Miller grinders.

3

Products

Since 1918

Established

Made in USA

Manufacturing

Livingston, NJ

Headquarters

Oil and Gas Products

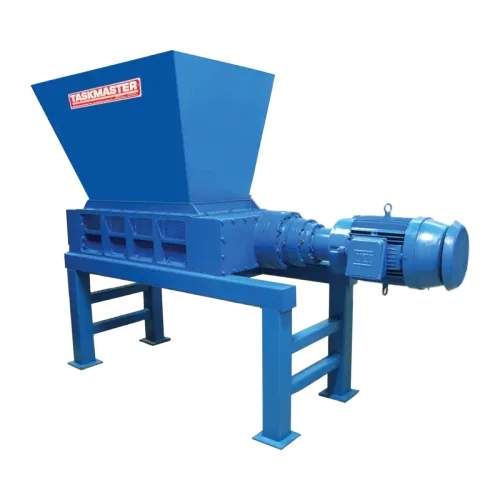

Taskmaster® TM8500

TASKMASTER® inline grinders employ a powerful twin-shaft mechanism and CUTTER CARTRIDGE® technology to reduce solids in pipeline systems. They are invaluable in plant operations worldwide keeping systems flowing, reducing pump downtime and protecting dewatering equipment such as centrifuges, filter presses and more. Two stacks of intermeshing cutters aggressively pull the solids in and finely reduce them. These grinders can be installed in gravity or pressurized, vertical or horizontal pipe systems, on the suction or positive side of a pump. The TASKMASTER® is provided with CUTTER CARTRIDGE® technology wherein 6 cutter disks and 6 spacer disks are replaced by one-piece elements for far greater strength, fewer components, no stack loosening or stack re-tightening requirement.

Oil and Gas Equipment

Franklin Miller has a multitude of inline processors suitable to handle the complex demands of oil and gas applications. The unique needs pertaining to the extraction, refining, and transporting of petroleum products can be easily handled by Franklin Miller grinders.

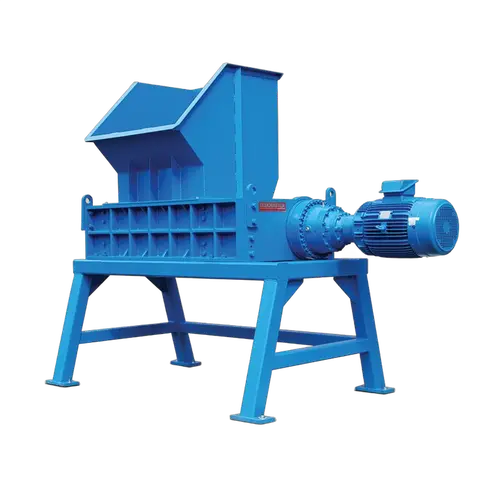

Oil and gas processing can wreak havoc on centrifuges and other expensive equipment. Franklin Miller inline processors such as TASKMASTER® Inline Grinders, DELUMPER® Crushers and SUPER SHREDDER® Inline Processors keep pumps and centrifuges protected by breaking down rocks and other debris before they can reach or damage downstream equipment.

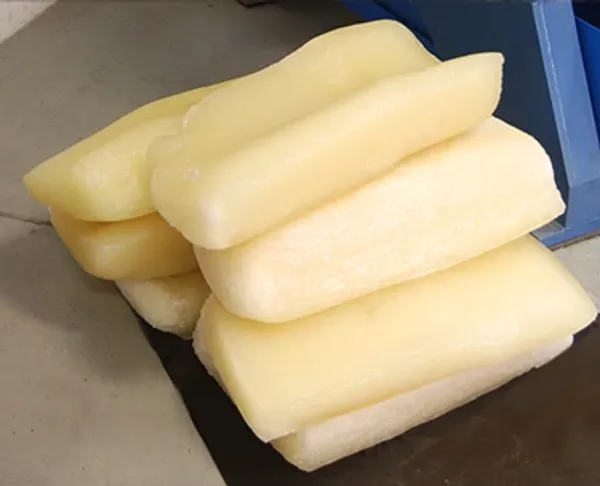

Oil Tailings Grinders

Used to transport oil tailings from mineral processing plants after ore processing. Tailings are the byproducts left over from mining and extracting resources, such as extracting bitumen from oilsands and mineral ores. Tailings include a mix of water, sand, silt, clay, finely ground rock particles and chemicals used to extract the valuable mineral or oil. In oil sand plants, this mix is often pumped over a long distance to release the bitumen. Franklin Miller processors help companies maintain the correct sized bitumen for refining.

Tank Cleaning

Sludge build up in crude oil storage tanks causes tanks to lose valuable storage space and lowers the capacity of the tanks. Franklin Miller’s powerful grinders can break down and process this excess sludge. By effectively grinding errant wood, build-up, slurry, resin, sludge, rocks, and other debris, our processors ensure downstream equipment will not be damaged and pumps will not be clogged. This helps ensure less downtime, money and time saved, and companies keeping to regulatory standards.

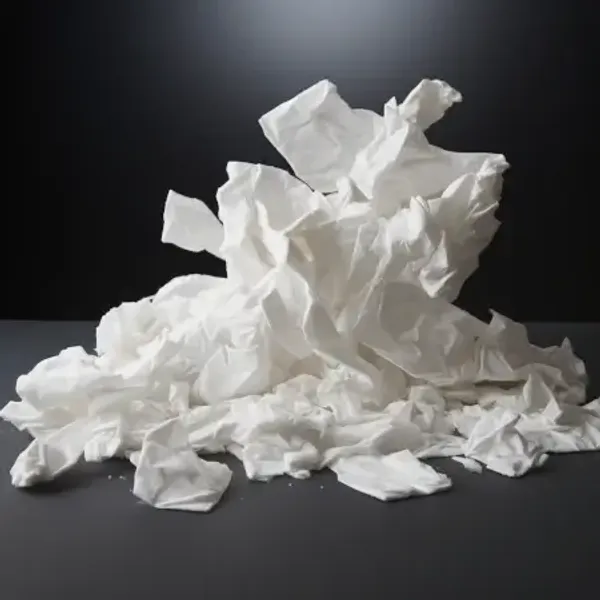

Pipeline Delumper®

The PIPELINE DELUMPER® is a proven inline lump breaker that chops, shreds, disperses and suspends solids directly in fully enclosed pipe systems. This straight-through ultra-compact unit rectifies flow properties of heavy sludge, slurries and solids-laden streams. The PIPELINE DELUMPER alleviates blockages, works the stream to free flow and improves processing. It can prevent damage to pumps, piping, valves, nozzles and downstream equipment. This unit has proven itself as a valuable problem solver in process systems worldwide.

Need Help With Your Oil and Gas Application?

Our engineers have decades of experience solving oil and gas challenges. Tell us about your process and we'll recommend the best fit.

Industries & Applications

Explore Other Industries

Trusted by Industry Leaders Worldwide

Engineering Excellence Since 1918

Let's Find the Right Solution for Oil and Gas

Our team is ready to help you select the right equipment for your oil and gas application and operating conditions.