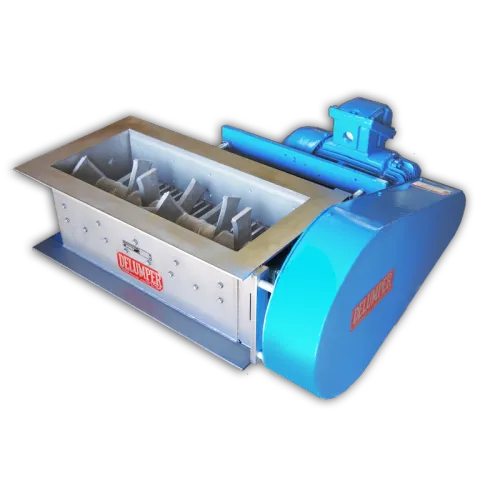

This unique automatic bag tipper coupled with a DELUMPER® Crusher makes unloading and conditioning of caked bagged material safe and easy.

The operator places the bag on the unit tray and secures it with clamps, cuts the bag and the unit does the rest. The tray automatically closes forming a front door of the hopper. The material drops out of the bag with the help of a unique agitator. The contents are discharged from the DELUMPER Crusher conditioned and deagglomerated, creating a freshened product, ready for further processing, conveying or sale. The crusher is fully enclosed while operating for maximum safety.

The DELUMPER can be supplied with a PLC-based control system that coordinates the motion of the tipper and DELUMPER. This unit is supplied in carbon steel as well as 304L and 316L stainless steel in standard and sanitary finishes. Options include a dust collector, explosion-proof drive and auxiliary conveying and weighing devices.